Analyser Shelters

Description

An Analyzer Shelter is a purpose-built, weatherproof enclosure used to install process analyzers, sampling systems, calibration equipment, and control panels in industrial plants. It is designed to provide a stable, clean, and temperature-controlled environment, ensuring accurate and continuous analyzer performance.

The shelter is typically fabricated from mild steel, stainless steel, or insulated panels, and can be equipped with HVAC systems, pressurization units, lighting, fire & gas detection, and electrical fittings as per site requirements. Analyzer shelters enhance personnel safety, equipment reliability, and compliance with international standards such as IEC, NEC, and ATEX (where applicable).

These shelters are commonly deployed in oil & gas, refineries, petrochemicals, fertilizer plants, and power plants, especially in outdoor or hazardous areas where environmental protection and operational integrity are critical.

Features

• Weatherproof and corrosion-resistant construction suitable for harsh industrial environments

• Thermally insulated panels for temperature stability and energy efficiency

• Designed to house analyzers, sampling systems, calibration panels, and control cabinets

• HVAC system to maintain controlled temperature and humidity

• Positive pressurization option to prevent ingress of dust, fumes, and corrosive gases

• Integrated lighting, power distribution, and earthing arrangement

• Fire & gas detection and alarm system (optional / as per project requirement)

• Safe and easy access with lockable doors and maintenance space

• Compliance with applicable international standards (IEC / NEC / ATEX / IS where required)

• Customizable layout and dimensions to meet client and site-specific requirements

Refinery Coolers

Description

A Refinery Cooler is a robust heat exchange unit designed to safely and efficiently reduce the temperature of high-temperature process fluids, steam, or condensate in refinery and petrochemical plants. It plays a critical role in protecting downstream equipment, piping, and instrumentation by ensuring process streams are cooled to safe, controlled levels before further processing, sampling, or analysis.

Manufactured using high-grade, corrosion-resistant materials such as stainless steel, refinery coolers are built to withstand high pressure, high temperature, and aggressive process conditions commonly found in refinery operations. The cooler provides stable thermal performance, minimizes thermal shock, and ensures consistent outlet temperatures under continuous operation. Its compact and maintenance-friendly design makes it suitable for integration into sampling systems, SWAS panels, and refinery utility lines, enhancing overall process safety, reliability, and operational efficiency.

Features

• Designed for high-temperature and high-pressure refinery process streams

• Efficient heat dissipation to ensure safe outlet temperatures

• Corrosion-resistant construction for harsh refinery and petrochemical environments

• Compatible with sampling systems, SWAS panels, and process utility lines

• Flexible mounting options for panel, skid, or field installation

• Leak-tight design ensures safe and reliable operation

Specifications:

| Specification | Details |

|---|---|

Closed Loop Sampling System

Description

A Closed Loop Sampling System is an advanced sampling solution designed to safely extract, analyze, and return process fluids or gases without venting them to the atmosphere. By maintaining a sealed circulation path, the system ensures zero emissions, minimal product loss, and maximum safety for operating personnel. It is especially suitable for handling hazardous, toxic, flammable, or high-pressure process media.

The system typically integrates isolation valves, pressure regulators, filters, coolers, flow control devices, and analyzers to deliver a representative sample under controlled conditions. After analysis, the sample is routed back to the process line or a designated return point, maintaining process integrity and environmental compliance. Closed Loop Sampling Systems are widely used in refineries, petrochemical plants, SWAS systems, gas processing units, and critical process monitoring applications, offering reliable performance, regulatory compliance, and long-term operational efficiency.

Features

• Sample Directly from Process High Sample Integrity

• Provides a simple, effective way to safely collect samples

• Keeps samples in their representative state for analysis

• Can be adapted to meet system requirements

• SEL manufacture and customized Sample systems with sample Bottles and sample cylinders

• Ease of maintenance

• Ease of Installation

• Self standing / Plate Mounted / fully Enclosed as per requirements.

Applications

• Oil And Gas Refineries

• Petrochemicals Industries

• Hydrocarbon Gases Or Liquids

• Pharmaceutical Applications

• High Purity Gas Analysis

• Hydrogen Cooled Electric Generators

• Furnace Or Heat Treating

PORTABLE AFTER CATION CONDUCTIVITY

Description

This portable system is available in two configurations: as a Trolley Mounted System or as a Hand Carry (can easily be carried in the hand). It consists of an After Cation Conductivity Meter for offline measurement of After Cation Conductivity values of various Steam-Watersamples (Feed -Water, Main-Steam, Condensate, etc.) available in the SWAS room. In general, the ACC values of these samples range from 0.06 to 1 micro siemens/cm. The instrument shall contain one Cation Column with resin, Sample Flow Indicator with needle valve, one conductivity Cell/Sensor, and one conductivity Value Display Unit (can be operated by a power supply 220 VAC 50 Hz and with battery power).

Features

• Sample Isolation Valves ¼” OD

• Cation Column with Resin in H+ Form

• Rotameter with Needle Valve

• SS316, 1/4” Flow Through Chamber for Conductivity Sensor

• Conductivity Analyzer with Sensor

• Pressure Regulator Sample Tubing – ¼” OD 5 Meter

• UPS Power Supply (For 4 Hrs of operation)

• Sample Drain Point

• Flexible Tubing 4-5 meters, 1/4” OD

Specifications:

| Specification | Details |

|---|---|

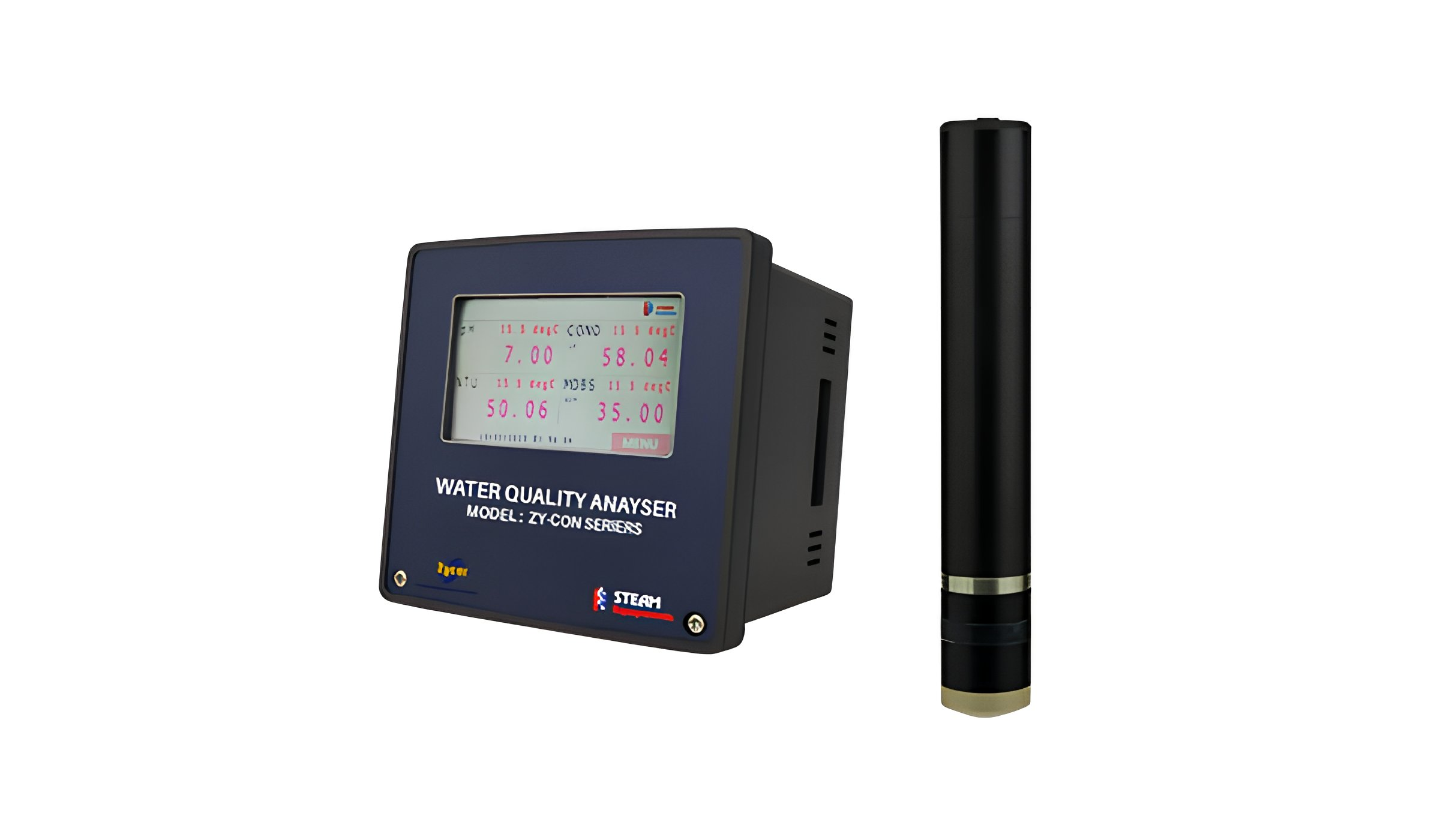

Online Low Range Turbidity Analyzer with Sensor

Features

• Stable Data and Good Repeatability: Provides reliable and consistent turbidity measurements

• Simple Cleaning and Maintenance: Easy-to-clean design reduces maintenance efforts

• Continuous Readings: Designed for continuous monitoring of turbidity levels

• Low-Range Turbidity: Suitable for measuring low levels of turbidity

Specifications:

| Specification | Details |

|---|---|

Phenol Analyzer Model: UV-con-phen

Specifications:

| Specification | Details |

|---|---|

Ammonia Nitrogen Analyzer UV-con-amni

Specifications:

| Specification | Details |

|---|---|

Hardness Analyzer Model: UV-con-hard

Specifications:

| Specification | Details |

|---|---|

Phosphate Analyzer Model: UV-con-phos

Specifications:

| Specification | Details |

|---|---|

Chloride Analyzer UV-con-chlo

Specifications:

| Specification | Details |

|---|---|

Oil In Water Analyzer Model: UV-con-oiw

Specifications:

| Specification | Details |

|---|---|

Coal Mill Co Online Monitoring System

Description

The UV-EX-COAL-C-230VAC coal mill CO online monitoring system is an early warning system for high CO concentrations. It reacts very quickly to changes in CO content before an open flame occurs. This system can provide an early warning of a coal mill fire based on the CO concentration produced during incomplete combustion, preventing damage to equipment and personnel. The GCEM1100CM coal mill CO online monitoring system consists of four parts: a sampling probe assembly, a preprocessing unit, an analysis unit, and a display unit. Based on dispersive infrared (NDIR) photoelectric detection technology and our company's mature preprocessing system, it features long service life, strong anti-interference ability, good stability, high measurement accuracy, and low maintenance difficulty.

Features

• Utilizing the principle of non-dispersive infrared (NDIR) and optical long-path absorption cell technology, it achieves high measurement accuracy and long service life;

• It includes an automatic calibration function to prevent gas detection drift.

• Configure zero-point calibration and full-scale calibration to ensure excellent linearity;

• The system employs a direct extraction sampling method with full-process high-temperature heating, ensuring high reliability, accurately reflecting the composition and content of flue gas without additional errors, and providing high measurement accuracy. The system also offers diverse configurations, allowing for the selection of electrochemical measurement modules based on actual operating conditions.

• The probe filter is manufactured using a special process, and the automatic purging configuration of the sampling pipeline ensures continuous sampling and long-term reliable operation of the system under high dust conditions.

Specifications:

| Specification | Details |

|---|---|

Online Suspended Solid Analyzer Model: UV-con-mlss

Specifications:

| Specification | Details |

|---|---|

Portable Oxygen Analyzer (AST)

Description

AST-1012 portable PPM O2 analyzer is powered by a rechargeable battery. AST-1012 PPM O2 analyzer offers user selectable any range from 0-5 PPM to 0-25%. Display resolution of 0.01PPM. Analog signal output is locked on the selected range. Fast recovery from air to 10 PPM in under 45 minutes.

AST-1012 portable PPM O2 analyzer comes with a standard PPM O2 sensor model AST-333. The AST-333 PPM O2 sensor is compatible with inert and gaseous hydrocarbon gas streams, and has 18 months expected operating life.

AST-1012 portable O2 analyzer can be used in an extended operating temperature range of -10°C (14°F) with optional Z series PPM O2 sensor model AST-333-Z. In addition to extended temperature range, the Z-Series sensors show excellent compatibility with gas streams containing any level of CO2. No routine sensor maintenance, other than periodic calibration, is needed. Analyzer is fitted with quick connect sample inlet and outlet fittings for quick and easy operation.

Features

• User Selectable Range From 0-5 PPM to 25%

• Output Locking on Selected Range

• Analog output 0-1 VDC Full Scale

• Fine Tuned Temperature Compensation for Enhanced Accuracy

• Barometric Pressure Compensation

• Intrinsically safe design complies with Class I Div I Group IIC when used with recommended battery

Specifications:

| Specification | Details |

|---|---|

Sulphide Analyzer

Specifications:

| Specification | Details |

|---|---|

Dissolved oxygen Analyser

Specifications:

| Specification | Details |

|---|---|

Fluoride Analyzer Model: UV-con-fluo

Specifications:

| Specification | Details |

|---|---|

Silica Analyzer Model: UV-con-sil-hr

Specifications:

| Specification | Details |

|---|---|

Chlorine Analyzer

Specifications:

| Specification | Details |

|---|---|

Online High Range Turbidity Analyzer with Sensor

Features

• Dual-Beam Infrared Scattered Light Photometer Detection: for accurate and stable measurements

• Built-in Self-Diagnosis Function: Ensures data accuracy and reliability

• Plug-and-Play Sensors: Quick and easy installation for user convenience

• Optional Automatic Cleaning Function: Reduces sensor maintenance and enhances usability

Specifications:

| Specification | Details |

|---|---|

COD, BOD, TSS, TOC ANALYZER WITH SENSOR

Features

• RS-485 output, support MODBUS

• No reagents, no pollution, more economical and environmentally friendly

• Can measure COD, BOD, TSS, TOC and other parameters

• Automatic compensation for turbidity interference for excellent performance

Specifications:

| Specification | Details |

|---|---|

Orp Sensor

Features

• Power supply and output isolation design to ensure electrical safety

• RS-485 transmission interface, MODBUS-RTU communication protocol, two-way communication

• Output more electrode diagnostic information, more intelligent

Specifications:

| Specification | Details |

|---|---|

Ph Sensor

Features

• Power supply and output isolation design to ensure electrical safety

• RS-485 transmission interface, MODBUS-RTU communication protocol, two-way communication

• Output more electrode diagnostic information, more intelligent

Specifications:

| Specification | Details |

|---|---|

Transmitter

Specifications:

| Specification | Details |

|---|---|

Tds Sensor

Features

• Power supply and output isolation design to ensure electrical safety

• RS-485 transmission interface, MODBUS-RTU communication protocol, two-way communication

• Output more electrode diagnostic information, more intelligent

Specifications:

| Specification | Details |

|---|---|

Conductivity Sensor

Features

• Power supply and output isolation design to ensure electrical safety

• RS-485 transmission interface, MODBUS-RTU communication protocol, two-way communication

• Output more electrode diagnostic information, more intelligent

Specifications:

| Specification | Details |

|---|---|

Conductivity/tds Transmitter

Specifications:

| Specification | Details |

|---|---|

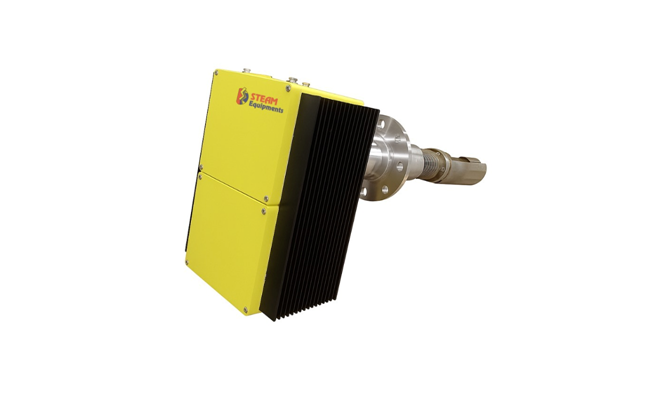

Zirconia Oxygen Analyzer

Description

MODEL: OXYMON

OXYMON Series Zirconia oxygen analyzer is an analyzer used to monitor and control the oxygen concentration of combustion gases, boilers and flue gas in industrial furnaces. It is widely used in industrial fields requiring a large amount of energy - such as steel mills, power plants, petroleum and petrochemical, ceramics, paper, food or textile industries, as well as various types of incinerators and medium/small boilers. In these areas, it can help save energy. It can also reduce the emissions of CO2, SOx and NOx by controlling complete combustion, and contribute to protecting the earth's environment, preventing global warming and air pollution.

The zirconia oxygen analyzer consists of a detection unit (oxygen probe) and a control unit (transmitter). Among them, the detection unit is installed on the flue, and the detector is composed of a dust proof device, zirconia tube, heating furnace, thermocouple, gas conduit, junction box and shell. The whole device adopts a fully enclosed structure to increase the sealing ability of the whole device and improve the service life. The control unit is the terminal for the user to operate the integrated functions, including the operation panel, the display interface, and the 4-20mA current output port. The oxygen analyzer with automatic calibration also includes a standard automatic order box.

Features

• Easy to Use and Low Maintenance

• The Sensor adopts Ion coating technology ,which has strong anti-oxidation ability

• long service service life

• The Unique thermal diffusion reference design does not need special reference air pump/Instrument Air

• Extremely Low Oxygen potential long-terms drift

• High measurement accuracy and stable and reliable data

• The sensor adopts unique welding process ,which has high sealing performance and No leakage

Specifications:

| Specification | Details |

|---|---|

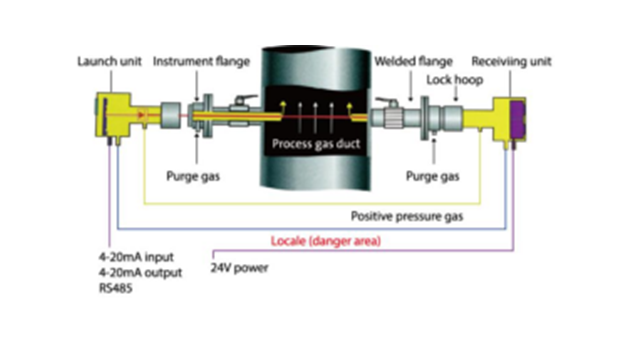

Process Gas Analyzer

Description

MODEL:OXYMON

OXYMON Series Zirconia oxygen analyzer is an analyzer used to monitor and control the oxygen concentration of combustion gases, boilers and flue gas in industrial furnaces. It is widely used in industrial fields requiring a large amount of energy - such as steel mills, power plants, petroleum and petrochemical, ceramics, paper, food or textile industries, as well as various types of incinerators and medium/small boilers. In these areas, it can help save energy. It can also reduce the emissions of CO2, SOx and NOx by controlling complete combustion, and contribute to protecting the earth's environment, preventing global warming and air pollution.

The zirconia oxygen analyzer consists of a detection unit (oxygen probe) and a control unit (transmitter). Among them, the detection unit is installed on the flue, and the detector is composed of a dust proof device, zirconia tube, heating furnace, thermocouple, gas conduit, junction box and shell. The whole device adopts a fully enclosed structure to increase the sealing ability of the whole device and improve the service life. The control unit is the terminal for the user to operate the integrated functions, including the operation panel, the display interface, and the 4-20mA current output port. The oxygen analyzer with automatic calibration also includes a standard automatic order box.

Model: UT-IN Online Series

UT-IN is a flameproof bypass type tunable laser gas analyzer for industrial on-line analysis and environmental on-line monitoring, especially suitable for harsh working condition such as high temperature, high humidity, high dust, and high board. The analyzer contains auto purge function with greatly reduces maintenance cost.

UT-IN laser gas analyzer consists of transmitter, received and gas cell. The transmitter drives the tunable diode to emit laser of certain wavelengths, which passes through the gas cell, then reaches the receiver. The receiver performs signal processing to obtain second harmonic signal, then calculates the concentration according to the relationship between the second harmonic signal and the gas concentration.

Model: UT-IN-S-N-O-H-230

SO2-NO2-CO2 measurement:

• This analyzer uses UV absorption (for SO₂ and NO₂) and IR spectroscopy (for CO₂) in a compact, robust sensing head with LED light sources and no moving parts, requiring virtually zero maintenance.

Accuracy is ensured through automatic zero calibration using ambient air, with CO₂ scrubbed by a long-life disposable filter (2+ years replacement interval).

• Service needs are minimal: 36V DC power (@50 VA) and RS485 digital output via a single 4-way sealed connector.

NO/H2O Measurement:

• The NO/H₂O sensor uses the same in-situ probe design as the SO₂/NO₂/CO₂ sensor but employs a Quantum Cascade Laser (QCL) as the radiation source. The QCL provides a narrow, precise IR beam, allowing measurement of a single NO absorption line free from H₂O interference for highly accurate, noise-free readings. It simultaneously measures H₂O concentration using a nearby spectral line.

• Unlike traditional chemiluminescence (maintenance-heavy) or IR/UV methods (cross-sensitivity and short lamp life issues), the QCL offers long-term stability, no moving parts, and virtually zero maintenance, with a lifetime measured in decades.

• The analyzer measures NO from <10 ppm to several thousand ppm at temperatures up to 450 °C and can be adapted for other gases (e.g., NH₃) by selecting a suitable QCL wavelength, making it ideal for applications like SCR control in coal-fired power plants.

Model: UT-IN-S-N-O-H-230VAC

UT-IN series Flue Gas Analyzer is a highly integrated single-flange gas monitoring equipment, of which, core detection module adopts Tunable Diode Laser Absorption Spectroscopy (TDLAS), Differential Optical Absorption Spectroscopy (DOAS) gas absorption technology and Zirconia with independent intellectual property rights. The specially designed measuring cell effectively improves optical path length for gas absorption, which can measure trace gas accurately inside pipeline UT-IN series can be widely applied in online gas monitoring occasions including denitrification device, boiler flue and exhaust detection, etc. One equipment can realize online monitoring for multiple gas components, such as CO, CO2, SO2, NO, NO2, O2, H2O etc.

MODEL: OXYMON-ZPM

It is widely used in N2 reflow furnace, N2 direct flow furnace, air separation device, gas puritymanagement, protective inert gas, ferrite sintering furnace and other environments to measureoxygen concentration

Model No: ZY-OXY-PM/PMD

The ZY-OXY-PM series paramagnetic gas analyzer is based on the characteristics of oxygen with high paramagnetic. It can detect various concentrations of oxygen such as trace oxygen, constant oxygen and purity oxygen. The magnetic mechanical principle has high analysis precision and long service life. It has non-explosion-proof and explosion-proof models and can be used in industrial hazard applications.

Model: UT-IN Series

The laser gas analyzer can measure high-temperature (700°C), high-dust (50g/m3) flue gas,and can realize in-situ analysis at the work site; and the laser gas analyzer has a short response time, which is a true "real-time online" analysis instrument. It can be used to measure CO, CO2, O2, NH3, HCL, HF, CH4 and other gases. Provide real-time and accurate data for process monitoring, safety monitoring, and pollution monitoring.

Features

• Easy to Use and Low

Maintenance

• The Sensor adopts Ion coating technology ,which has strong anti-oxidation ability

• long service service life

• The Unique thermal diffusion reference design does not need special reference air pump/Instrument Air

• Extremely Low Oxygen potential long-terms drift

• High measurement accuracy and stable and reliable data

• The sensor adopts unique welding process ,which has high sealing performance and No leakage

• Suitable for harsh working conditions such as hightemperature, high humidity, high dust, high pressure,

• and for small pipes where a are not suitable for inside measurement occasions.

• Integrated structure design, high reliability and

• Stability

• “Single Line Spectrum”

• Technology, free from interface of background

• Gas.

• Innovative Hall button design, high sensitivity,

• Easy operation.

• Adopts imported TO encapsulate semiconductor laser, optical noises are restrained with antireflective coating end cap.

• Easy installation and operation

• Low maintenance

• INSITU CEMS suitable for Refineries, power plant & other industries.

• Measurement gas resolution 1 PPM and accuracy +/-2% of reading

• UV absorption spectroscopy based SO2 & NO2 measurement, Laser (QCL) based NO & H2O measurement and Infrared spectroscopy-based CO2 measurement

• Remote monitoring of system available.

• Simple Installation as per the photograph

• Light weight so easy to installation.

• Low maintenance cost

• No Shelter required

• Adopt single-flange design with high integration

• and easy installation

• Measurement gas resolution 1 PPM and accuracy +/-2% of fs

• Remote monitoring of system available.

• Simple Installation as per the photograph

• With high-temperature flowmeter, user can

• observe flow during equipment operation

• Low maintenance cost

• Sampling measurement is free from interference of pipeline deformation, high dust and other working condition change, with strong adaptability

• No Shelter required

• The imported new-type longevously zirconia detector is with high accuracy and a rapid response speed for features, etc.;

• N2 or O2 Display mode available;

• The auto-compensation system for temperature with high accuracy could eliminate the influence from the environment temperature;

• The accurate measurement of oxygen concentration among the range of ppm~% can be met through one-point calibration in the air;

• The size is small and easy to maintain;

• The auto-compensation system for temperature with high accuracy could eliminate

• the influence from the environment temperature.

• The upper and lower alarm limits can be set freely among the whole range

• The mechanical dumbbell type paramagnetic principle has high precision, short preheating time, quick response and good linearity,

• Direct measurement of the paramagnetic properties of oxygen with low gas interference.Compared to electrochemical sensor, it adopts non-consumable components, the normal lifespan can last over 1O years.Trace, constant, purity oxygen, multi-range is optional. LCD display, concentration curve, history data and other information display.

• RS485 signal output, relay output, compatible with various control systems. Standard 19-inch chassis design(non-explosion-proof}, can be equipped with sampling system for mast of working conditions.

• Thick carbon steel casing {explosion-proof type). explosion-proof grade up to ExdllCT6, can be used in explosive hazardous areas.

• Soft boot and watchdog functions, to keep a stable work without crash

• High Precision, Extremely Low Drift

• High selectivity, No Cross interference

• High temperature gas can be measured, up to 700 deg C

• It can measure complex gas mixture and their component changes

• No affected by dust

• Reponse time <1s

• Long maintenance period and low cost

• long service service life

• Suitable up to 50 g/m3 dust load

Specifications:

| Technical Parameter | Specification |

|---|---|

| Model No. | UT-IN Series |

| Measuring Principle | TDLAS (Tunable Diode Laser Absorption Spectroscopy) |

| Measuring Gas Chamber Length | 200–1000 mm |

| Measuring Gas Chamber MOC | SS316L / Hastelloy (Customizable) |

| Preheating Time | < 15 minutes |

| Response Time (T90) | < 30 seconds (depending on working conditions) |

| Accuracy | ±1% FS |

| Span Drift | ±1% FS |

| Repeatability | ±1% FS |

| Maintenance Intervals | < 2 times/year, clean optical window (no consumables needed) |

| Calibration Intervals | < 2 times/year |

| Operating Temperature | Up to 700°C |

| Protection Class | IP66 |

| Area Classification | Suitable for hazardous areas (Exd IIC T6) |

| Analog Signal Output | 4–20mA isolated current output (max load 500 ohms) |

| Analog Input | 4–20mA current (temperature and pressure compensation, optional) |

| Digital Output | RS485 / RS232 |

| Relay Output | 3-wire output (24V, 1A) |

| Power Supply | 24VDC / 110–230VAC, 50/60Hz, <40W |

| Purge Gas | 2–8 bar Industrial N₂ or Purified Instrument Air |

| Ambient Temperature | –20°C to +60°C |

| Transmitter & Receiver Enclosure | Cast aluminum shell |

| Installation | Wall-mounted |

| Sample IN/OUT Connection | 6mm / 8mm (customizable as per requirements) |

| Parameter | Description |

|---|---|

| Measurement | SO₂, NO₂, CO₂, NO / H₂O |

| Technology | SO₂–NO₂–CO₂: UV Absorption Spectroscopy NO / H₂O: Quantum Cascade Laser (QCL) |

| Range (SO₂–NO₂–CO₂ Measurement) | SO₂: 0 to 500 / 1000 ppm NO₂: 0 to 500 / 1000 ppm CO₂: 0 to 10% (Other measurement ranges customizable) |

| Range (NO–H₂O Measurement) | NO: 0 to 500 / 1000 ppm H₂O: 0–20% (Other measurement ranges customizable) |

| Probe MOC | SS 316 |

| Accuracy | SO₂: ±2 ppm or ±2% of reading NO₂: ±2 ppm or ±2% of reading CO₂: ±0.1% CO₂ NO: ±1 ppm or ±2% of reading H₂O: ±0.1% H₂O |

| Resolution | SO₂ / NO₂ / NO: 1 ppm CO₂ / H₂O: 0.1% |

| Protection Level | IP65 |

| Probe Length | 300 mm / 500 mm / 1000 mm (customizable per site requirements) |

| Response Time | T90 < 100 seconds |

| Analog Output | Each parameter 4–20 mA output |

| Digital Interface | RS485 (Modbus) |

| Ambient Temperature | –20°C to +55°C |

| Power Supply | 100–240 VDC, ±10% FS, 50/60 Hz |

| Purging | Instrument Air |

| Calibration Facility | Using Calibration Standard Cylinder |

| Work Temperature (Flue Gas) | 0°C to 450°C |

| Weight | < 30 kg |

| Parameter | Description |

|---|---|

| Measurement | SO₂, NO, NO₂, CO, CO₂, O₂ / H₂O |

| Measurement Technology | SO₂ / NO / NO₂: DOAS (Ultraviolet Differential Absorption Spectroscopy) CO / CO₂: TDLAS (Tunable Diode Laser Absorption Spectroscopy) O₂ / H₂O: Zirconia-based Sensor |

| Measurement Range | SO₂: 0 to 500 / 1000 / 2000 / 3000 / 5000 ppm NO: 0 to 500 / 1000 / 2000 / 3000 / 5000 ppm NO₂: 0 to 500 / 1000 / 2000 / 3000 / 5000 ppm CO: 0 to 500 / 1000 / 2000 / 3000 / 5000 ppm CO₂: 0 to 20 / 25% O₂: 0 to 20 / 25% H₂O: 0 to 40% (Other measurement ranges customizable) |

| Probe MOC | SS316 / SS316L |

| Probe Length | 500 mm / 1000 mm / 1500 mm / 2000 mm (customizable as per site requirements) |

| Accuracy | ± 2% FS |

| Repeatability | ± 1% FS (under standard conditions) |

| Resolution | SO₂ / NO / NO₂ / CO: 1 ppm CO₂ / H₂O: 0.1% |

| Zero Drift | ± 2% FS / 30 days |

| Span Drift | ± 2% FS / 30 days |

| Protection Level | IP65 |

| Response Time | T90 < 90 seconds |

| Analog Output | Each parameter 4–20 mA output |

| Digital Interface | RS485 (Modbus) |

| Ambient Temperature | –20 °C to +60 °C |

| Ambient Humidity | ≤ 90%, non-condensing |

| Power Supply | 110 / 240 VDC, ±10% FS, 50/60 Hz |

| Instrument Air Supply | 3–5 bar, oil-free, water-free and dust-free air |

| Calibration Facility | Using calibration standard cylinder |

| Work Temperature (Flue Gas) | 0 to 350 °C |

| Weight | < 45 kg |

| Parameter | Description |

|---|---|

| Model No. | OXYMON-ZPM |

| Measurement Display | O₂ or N₂ |

| Measuring Principle | Zirconia |

| Measuring Range | 0–10 / 100 / 1000 PPM / 21% (User Configurable) |

| Accuracy | ± 1.5% FS |

| Repeatability | ± 1.0% FS |

| Operating Temperature | 0°C to 60°C |

| Ambient Temperature | –10°C to 50°C |

| Sample Mode | Sample Gas In |

| Sample Gas Flow | 300–500 ml/min |

| Sample Gas Pressure | 95 kPa – 105 kPa |

| Sample In & Out Port Size | 6 mm |

| Response Time | T90 < 30 seconds |

| Background Gas | Nitrogen and Oxygen mixed gas |

| Power Supply | 85–240 VAC, 50/60 Hz, 250 VA |

| Analogue Output | 4–20 mA Isolated, 500 Ω max |

| Size (HxWxD) | 80 × 160 × 142 mm |

| Install Cut Out (HxW) | 76 × 151 mm |

| Relay Output | 1 No. potential-free contact |

| Service Life | > 22,000 hours (under normal use) |

| Install Mode | Frame mount or retaining clamp carried by the Oxygen sensor |

| Parameter | Description |

|---|---|

| Model | ZY-OXY-PM: Non–Explosion Proof ZY-OXY-PMD: Explosion Proof |

| Measuring Range | O₂: 0–5% / 15% / 30% / 100% VOL |

| Principle | Customized Paramagnetic |

| Accuracy | ± 0.1% VOL |

| Resolution | 0.01% / 0.1% VOL (depending on range) |

| Repeatability | ± 0.5% |

| Zero Drift | ± 0.5% FS / 7 days |

| Span Drift | ± 0.5% FS / 7 days |

| Response Time (T90) | ≤ 5 seconds |

Description

The SE - DEW - 100 Dewpoint Transmitter makes monitoring dewpoints as easy as measuring temperature or pressure, and can be instantly incorporated into air or gas measurement and control systems. We highly automated manufacturing, calibration and test processes make the SE - DEW - 100 not only a very rugged and reliable instrument but also very competitive in price. By taking advantage of sensor program, users can be assured that their process moisture measurement facility is never interrupted. It is very easy to install and maintain and comes with a full world-wide backup and service program.

Features

• 4-20 mA 2-wire loop powered connection

• Dewpoint OR parts per million (moisture content) in volume (PPM(V) measurements

• Accuracy ±2°Cdp

• Repeatability ±0.5°Cdp

• Dewpoint values traceable to international standards

• Excellent detector element protection

• Rugged stainless steel construction

• Fully interchangeable

Applications

- Compressed Air

- CNG Stations

- Moisture in Liquids

- Medical Gas

- Trace Moisture

Specifications:

- Measurement Range: -100 to +20°C dew point

- Accuracy: ±2°C dew point

- Response Time: 1 minute to T95 (dry to wet)

- Repeatability: 0.5°C dew point

- Calibration: Traceable 7-point calibration certificate

- Output Signal: 4–20 mA (2-wire)

- Supply Voltage: 8–36 V DC

- Current Consumption: 20 mA max

- Operating Temperature: -40 to +60°C

- Operating Humidity: 0–100% RH

- Flow Rate:

0.2 to 5 Nl/min (mounted in standard sampling block)

0 to 10 m/s (direct insertion)

- Temperature Coefficient: Temperature compensated across operating range

- Ingress Protection: IP65

- Housing Material: Stainless steel

- Dimensions: 114 mm length × 30 mm diameter

- Weight: 170 g

- Filter: 20 µm sintered guard

Ranges:

Range by sensor type:

XTR-100 -148° to 68°F (-100° to 20°C)

XTR-65 -85° to 68°F (-65° to 20°C)

Pressure Operating Range:

Standard 500 psi (34 Bar)

Optional 5,000 psi (340 Bar)

Readouts: Dewpoint in °F and °C, ppmv, H2O/m3, lbs H2O/mmscf

Sensor Type: High capacitance Al2O3 (HTF)

Accuracy: ± 5.5°F (± 3°C)

Repeatability: ± 0.9°F (± 0.5°C)

Capacitance: 15 nF to 200 nF

Temperature:

Sample: 22° to 122°F (-30° to 50°C)

Electronics: 14° to 122°F (-10° to 50°C)

Response Time:

For a step change from -40° to -76°F (-40° to -60°C)

63% in 90 seconds

90% in 450 seconds

Mechanical Connections:

14 mm x 1.25 mm threads and 3/4″ – 16 threads

Flow cell with 1/4″ tube fitting (option)

Electrical Connections: Female BNC connector

Intrinsically Safe Option: Class 1 & 2, Division 1, Groups A, B, C, D, E, F & G

(when used with optional safety barriers)

Display/Indicator: Back-lit LCD, 3.5 digits

Controls: 4 push buttons

Power: 100-240 VAC, 50/60 Hz

Output: 0/4-20 mA, RS-232

Sensor Cable: Coaxial cable (75Ω with capacitance of 50 pF/M)

Maximum cable length = 3,000 ft (914.4 m)

Flow Meters

Description

ECO-FLASH, flash vessels are used for separation of flash steam from high pressure condensate thereby generating useful low pressure steam totally free of cost. ECO-FLASH is supplied with all standard accessories like safety valve, pressure gauge, Valve, double window sight glass, steam trap and strainer.

A flow meter is a device used to measure the volume or mass of a gas or liquid. Flow meters are referred to by many names, such as flow gauge, flow indicator, liquid meter, flow rate sensor, etc. depending on the particular industry. However, they all measure flow. Improving the precision, accuracy, and resolution of fluid measurement are the greatest benefits of the best flow meters.

Features

• Wide range of nominal diameter Size ½” to 28” (15 mm to 700 mm) with IP68 protection

• Easy maintenance due to no moving parts

• Uninfluenced by temperature, pressure, viscosity, and density

• Used for wide application, can measure conductive fluid, without reference to fibre, solid or suspending material contained in liquid

• High turndown ratio up to 1:100

• It features high intelligence, with back light LCD display, menu setting control, three grades password protection, two-way measuring, slight signal removal, auto flow compensation, and other function.

• Features high intelligence, which ensure empty pipe detection, self-detection, self-diagnostic functions, and safety alarms for upper and lower limit

• Features SMART excitation, which ensures zero-point stability, high reliability, and low power consumption

• Lining and electrode available in various materials which can measure nearly all conductive fluids

• It has multiple signal output, pulse, Modbus RS485 or HART® or 4 to 20 mA

• It has lower measuring limit, better stability, and accuracy

• It has a unique dual sensor design

• Special signal processing method provides better antivibration

• More reliable performance

• Requires less maintenance

• It can calculate density and mass flow rate without mass flow computer

• It has self-diagnostic function

• Optional multivariable version is available, has in-built RTD and pressure sensor that can measure and display flow rate, velocity, temperature, pressure, mass flowrate, and density

• Self-diagnostic function is available

• Measurement of mass flow, density, temperature and volume flow

• Suitable for aggressive and contaminated media

• Measurement and display of percent water-cut for oil/water mixtures

• High rotation frequency and well-balanced measuring tubes

• Higher Sampling and Digital Filtering

• No moving parts

• Can be used in extreme harsh conditions

• High accuracy for measuring mass flow, density, temperature and volume flow

Benefits

• Wide range of nominal diameter Size ½” to 28” (15 mm to 700 mm) with IP68 protection

• Easy maintenance due to no moving parts

• Uninfluenced by temperature, pressure, viscosity, and density

• Used for wide application, can measure conductive fluid, without reference to fibre, solid or suspending material contained in liquid

• High turndown ratio up to 1:100

• It features high intelligence, with back light LCD display, menu setting control, three grades password protection, two-way measuring, slight signal removal, auto flow compensation, and other function.

• Features high intelligence, which ensure empty pipe detection, self-detection, self-diagnostic functions, and safety alarms for upper and lower limit

• Features SMART excitation, which ensures zero-point stability, high reliability, and low power consumption

• Lining and electrode available in various materials which can measure nearly all conductive fluids

• It has multiple signal output, pulse, Modbus RS485 or HART® or 4 to 20 mA

• It has lower measuring limit, better stability, and accuracy

• It has a unique dual sensor design

• Special signal processing method provides better antivibration

• More reliable performance

• Requires less maintenance

• It can calculate density and mass flow rate without mass flow computer

• It has self-diagnostic function

• Optional multivariable version is available, has in-built RTD and pressure sensor that can measure and display flow rate, velocity, temperature, pressure, mass flowrate, and density

• Self-diagnostic function is availablet

• Measurement of mass flow, density, temperature and volume flow

• Suitable for aggressive and contaminated media

• Measurement and display of percent water-cut for oil/water mixtures

• High rotation frequency and well-balanced measuring tubes

• Higher Sampling and Digital Filtering

• No moving parts

• Can be used in extreme harsh conditions

• High accuracy for measuring mass flow, density, temperature and volume flow

Applications

• It can measure highly corrosive medium such as concentrated acid and concentrated alkaline using PTFE lining material.

• By using Hastelloy C electrode we can measure seawater and brine application Trace humidity in oxygen purity.

• It is used to measure gas, steam, and liquid.

• Cleaning and Sterilization (SIP and CIP) process in food, beverage, and pharmaceutical industries

• It is used in various industries like petrochemical, water and waste water, food and beverages

• Used to measure steady uniform flow of common viscous fluid, non-Newtonian fluid, slurry containing some solid components, and liquids containing some trace of gases.

• Suitable for the bulk measurement of products like syrup, molasses, and raw chemicals.

Specifications:

Service: Compatible conductive liquids

Measuring Range: flow range please refer the catalog

Lining Materials: PTFE and Synthetic rubber

Electrode Material: Stainless Steel, Hastealloy C

Accuracy: ±0.5%

Repeatability: 0.15%

Ambient Temperature Limits:

sensor (Remote Mount): -4 °F to 158 °F (-20 °C to 70 °C)

Converter: -4 °F to 122 °F (-20 °C to 50 °C)

Integral Type: 14 °F to 122 °F (-10 °C to 50 °C)

Ambient Magnetic Field: ≤ 400 A/m

Pressure Limit: ≤ 150 PSI

Mounting Orientation: Horizontal or vertical

Process Connection: #150 ANSI or AWWA flanges

Output Signal: Pulse and 4 to 20 mA or Modbus RS485 or 4 to 20 mA with HART

Power Requirements: 18 VDC to 28 VDC or 85 VAC to 220 VAC

Conductivity: ≥5 μs/cM

Enclosure Rating: IP68

Agency Approvals: CE

Service: Liquids, Gas, Steam

Max. Flow Range :

Gas: 197 ft/s

Liquid: 23 ft/s

Steam: 230 ft/s

Accuracy: ±1% of reading

Repeatability: 0.3% of reading

Ambient Temperature Limits: -40 °F to 662 °F (For standard vortex only)

Pressure Limit: As per flange rating

Mounting Orientation: Horizontal

Process Connection: Wafer or ANSI flange

Output: 4 mA to 20 mA or Pulse or 4 mA to 20 mA with HART or Modbus RS485

Power Requirements: 24 VAC or 13.5 VDC to 42 VDC

Enclosure Rating: NEMA 4x (IP67)Agency Approvals: CE

Service: Liquids and Gas

Size:

U shaped: 1½” to 8″

Microbend: ½” to 8″

Triangle: ½” to 1″

Measuring Ranges: For mass flow rates please refer the catalog

Accuracy: 0.1% or 0.2% or 0.5%

Density Measuring Range: 2 to 30 lb/gal (0.2 to 3 g/cm3)

Density Basic Error: ±0.02 lb/gal (±0.002 g/cm3)

Density Repeatability: ±0.01 lb/gal (±0.001 g/cm3)

Repeatability:

For 0.1% accuracy : ±0.05%

For 0.2% accuracy: ±0.1%

For 0.5% accuracy: ±0.25%

Temperature Limits:

Direct Mount: -58 °F to 257 °F (-50 °C to 125 °C)

Remote Mount: -58 °F to 392 °F (-50 °C to 200 °C)

Power Requirements: 18 VDC to 28 VDC or 85 VAC to 220 VAC

Output signal: 4 -20 mA or Pulse, Optional: HART or Modbus RS485

Description

The Quench Water Sampler is used to take water samples from high-temperature and high-pressure lines for pH measurement. It cools the hot water sample to a safe temperature before it reaches the pH analyzer. This helps to protect the sensor and ensures accurate and reliable pH readings. The system is made of stainless steel for long life and safe operation.

Sampling System for Gas Detection Systems

Features

- Designed for high-pressure and high-temperature applications.

- Built-in cooler to reduce sample temperature.

- Provides accurate and stable pH readings.

- Made from corrosion-resistant stainless steel (SS316).

- Compact and easy to install.

- Low maintenance design.

- Suitable for online or offline pH measurement.

- Continuous and reliable gas sampling from remote or inaccessible locations

- Compact, modular, and easy-to-install design

- Compatible with various gas analyzers and sensors

- Corrosion-resistant stainless steel or aluminum construction

- Integrated sample conditioning (filters, coolers, flow control)

- Low maintenance and easy access for servicing

- High accuracy and repeatability of gas measurements

- Optional alarm and safety interlocks

• Suitable for sampling seawater at different depths and locations

• Corrosion-resistant construction (SS316, titanium, or specialized alloys)

• Compact, modular, and easy to install on ships, platforms, or coastal stations

• Optional automated or manual operation

• Sample conditioning (filters, flow control) to protect analyzers

• Compatible with online analyzers or offline laboratory testing

• Low maintenance and long service life

Benefits

- Enables safe monitoring of hazardous areas

- Protects gas analyzers from moisture, dust, and temperature effects

- Ensures accurate and stable gas readings

- Reduces maintenance and downtime

- Customizable per process or analyzer requirements

- Improves plant safety and compliance with emission standards

• Ensures accurate and representative samples for analysis

• Protects sensors and analyzers from salt and debris

• Enables continuous or periodic monitoring of seawater quality

• Reduces human error and manual handling risks

• Enhances environmental compliance and research quality

• Robust design suitable for harsh marine environments

Applications

- Power plants (boiler and condensate systems)

- Refineries and petrochemical plants

- Chemical and fertilizer industries

- Water treatment plants

- Steam and water analysis systems (SWAS)

- Power plants (flue gas and emission monitoring)

- Refineries and petrochemical plants

- Steel and cement industries

- Fertilizer and chemical plants

- Waste incineration and environmental monitoring

- Gas turbine and boiler exhaust systems

Specifications:

- Sampling Flow Rate: 0.5 – 5 LPM (adjustable)

- Sample Pressure: Up to 10 kg/cm²

- Sample Temperature: Up to 150°C

- Sample Line Length: Up to 50 meters (depending on design)

- Material of Construction: SS304 / SS316 / Aluminum

- Filtration: 5-micron replaceable filter

- Power Supply: 230 VAC / 24 VDC (as required)

- Mounting Type: Wall Mounted / Skid Mounted

- Cooling Medium: Air or Water (if required)

- Analyzer Interface: Suitable for online gas analyzers

- Operating Temperature: 0°C – 55°C

- Enclosure Rating: IP54 / IP65

• PVDF/CPVC, Monel tube

• Sample coolers with PVDF, CPVC, PTFE material and wetted parts

• Filters with wetted parts of PVDF/CPVC/Monel

• Flow meters

• Mounting plate with 5 mm thick CPVC sheet

• Suitable for Desalination plants, Sea water quality monitoring, Effluent monitoring

• Oil in water sampling systems

• Salinity Analyzer

• Turbidity Analyzer

• pH and conductivity sampling systems

| Sr. No. | Parameter | Specification |

|---|---|---|

| 1 | Sample Pressure | Up to 100 kg/cm² |

| 2 | Sample Temperature (Inlet) | Up to 300°C |

| 3 | Sample Temperature (Outlet) | 25°C to 40°C (after cooling) |

| 4 | Cooling Medium | Cooling Water |

| 5 | Flow Range | 100 – 500 ml/min (adjustable) |

| 6 | Construction Material | SS316 / SS316L |

| 7 | Connection Type | ¼” or ½” NPT / Compression Fittings |

| 8 | Mounting Type | Wall Mounted / Panel Mounted |

| 9 | Application Medium | Quench Water / Condensate / Boiler Feedwater |

| 10 | Measurement Parameter | pH (via Analyzer / Electrode) |

| 11 | Design Type | Compact and Modular |

| 12 | Cooling Type | Counter Flow Cooling Arrangement |

| 13 | Maintenance | Easy to Service and Clean |

| 14 | Operating Environment | Indoor / Outdoor (as per system design) |

Degassed Cation Conductivity

Description

A new design for conductivity measurement for power cycle chemistry monitoring. By providing conductivity measurement in compliance with ASTM D4519, this system provides assurance of water purity to maximize power production and minimize corrosion. Unambiguous measurement of trace levels of corrosion causing contaminants is enabled with effective operator supervision. A must product for startup and supercritical Boilers

Features

• All conductivity measurements

• No external cooling water required

• Stainless steel construction

• Multi-parameter transmitter with single-screen display of all measurements

• Very High Accuracy

• Auto Ranging

• Integrated flow sensor with automatic heater shut-off if flow stops

• Precise detection of corrosive contaminants

• Inferred pH and CO2

• Trend graphs for all measurements

• Universal PCB

• Digital Sensors

• Emergency stop button

• Low flow cutoff

Benefits

• Faster Plant startups and simpler turbine warranty compliance

• Easy displaying and monitoring of sample conditions

• Protects the system from thermal damage and maintenance

• Understand plant characteristics better and plan maintenance, avoiding plant shutdowns

• Colour indicating Resin for depletion

• Alerts for changeover of Cation Column

Applications

• Feed Water and Steam Monitoring

• Power Plant Steam Quality Monitoring

• Power Plant Condensate Monitoring

Specifications:

Measuring principle: Degassing by heating

Measurements: Continuous Flow through type for Continuous measurement of Specific Conductivity, Cation Conductivity, Degassed Cation Conductivity values

Measuring Range:

a. Specific conductivity-0-100µS/cm

b.Cation conductivity- 0-10µS/cm

c. Degas conductivity-0- 1µS/cm

d.Freely programmable

No of stream: Single

Accuracy: < +/-1 % of fs

Response Time: T90 <=5 sec

Temperature Compensation: Automatic

Analog Output: Separate 4-20mA outputs for transmitting specific conductivity , Cation conductivity and Degassed Cation conductivity

Display: Larger Touch screen ,5.7” resolution 320×240 pixels,QVGA256 colors

Power Supply: 220-240 VAC,50 Hz

Ambient Temperature: 5 to 45 deg C

Relative Humidity: 10 to 90% non-condensing

Sample Flow Rate: 100-250 mL/min

Sample Temperature & Pressure: 10 to 45 degC &:0.2 to 4 Ksc

Ratings / Approvals: IP 65

Panel Body materials: SS316

Wetted part materials: SS316

Mounting: Plate mounting as per provided site conditions.

Sampling system:

SS 316 wall mounted sampling system

• Needle valve-1/4” SS316

• Pressure regulator

• Rota meter with regulator

• Flow through chamber

• Heater

• Cooling system

• SS sample tubing’s and fittings.

Chiller

Description

SEL’s chiller is designed with sufficient refrigeration capacity to ensure that sample stream temperature is up to 25oC ±1oC. It is fabricated with complete stainless-steel construction. Chiller is of direct expansion type with refrigerant tubes inside a shell, completely insulated and to be constructed in accordance with the ASME code. Refrigerant circuit consists of components such as thermostatic expansion valve, liquid line solenoid valve, sight glasses, filter-dryer, refrigerant shut-off and charging valves.

All Systems are designed in compliance with ASME PTC-19.11, USA, GDCD, UK, EPRI, VGB Standard S006-2012

Features

• Compact skid mounted chiller system, ready to install.

• Chillers are fully automatic with tried & tested controls.

• Quick chilling is ensured with plate type or shell and tube evaporators.

• Chillers use energy saving with cycling fans and high efficiency fin tube air-cooled condensers with liberal sized fans.

• Chillers offer guaranteed cooling capacity at rated parameters.

• Specific design to meet customer requirement for various temperatures available in addition to standard models.

Applications

• In sample handling systems, chillers are used to achieve outlet temperature of sample at 25oC. Chiller package is one of the important & valuable element of SWAS Unit.

Description

The shelter is constructed as a fully insulated sandwich construction with CRCA / SS-304 / SS-316L, making it suitable for ambient conditions. We have customized solutions for the customer. It can be provided with HVAC system. The complete shelter is designed, fabricated and tested in-house as an integrated system. The design of the analyzer shelter consider many factors like Local ambient conditions, hazardous area classification, sample type, analyzer type together with client specifications, will all influence the final design and content of the shelter.

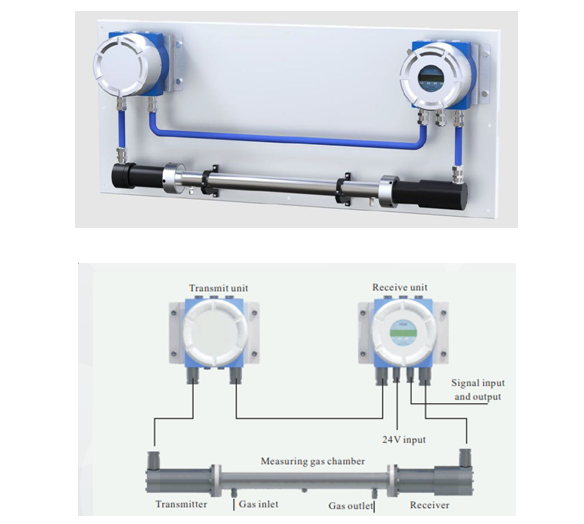

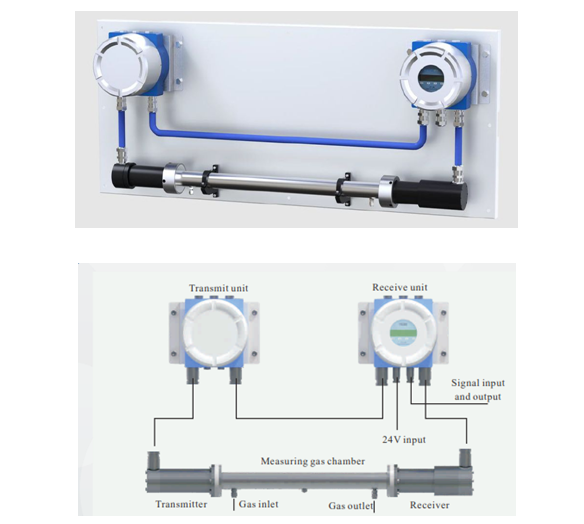

Tdlas Based Online Analyzer

Description

UT-IN is a flameproof bypass type tunable laser gas analyzer for industrial on-line analysis and environmental on-line monitoring, especially suitable for harsh working condition such as high temperature, high humidity, high dust, and high board. The analyzer contains auto purge function with greatly reduces maintenance cost.

UT-IN laser gas analyzer consists of transmitter, received and gas cell. The transmitter drives the tunable diode to emit laser of certain wavelengths, which passes through the gas cell, then reaches the receiver. The receiver performs signal processing to obtain second harmonic signal, then calculates the concentration according to the relationship between the second harmonic signal and the gas concentration.

Features

• Suitable for harsh working conditions such as hightemperature, high humidity, high dust, high pressure,

• and for small pipes where a are not suitable for inside measurement occasions.

• Integrated structure design, high reliability and

• Stability

• “Single Line Spectrum”

• Technology, free from interface of background

• Gas.

• Innovative Hall button design, high sensitivity,

• Easy operation.

• Adopts imported TO encapsulate semiconductor laser, optical noises are restrained with antireflective coating end cap.

• Easy installation and operation

• Low maintenance

Specifications:

| Specification | Details |

|---|---|

Oxygen Analyser (SEL)

Description

MODEL: OXYMON-ZPM

It is widely used in N2 reflow furnace, N2 direct flow furnace, air separation device, gas puritymanagement, protective inert gas, ferrite sintering furnace and other environments to measureoxygen concentration

Features

• The imported new-type longevously zirconia detector is with high accuracy and a rapid response speed for features, etc.;

• N2 or O2 Display mode available;

• The auto-compensation system for temperature with high accuracy could eliminate the influence from the environment temperature;

• The accurate measurement of oxygen concentration among the range of ppm~% can be met through one-point calibration in the air;

• The size is small and easy to maintain;

• The auto-compensation system for temperature with high accuracy could eliminate

• the influence from the environment temperature.

• The upper and lower alarm limits can be set freely among the whole range

Specifications:

| Specification | Details |

|---|---|

Paramagnetic Oxygen Analyzer

Description

Model No: ZY-OXY-PM/PMD

The ZY-OXY-PM series paramagnetic gas analyzer is based on the characteristics of oxygen with high paramagnetic. It can detect various concentrations of oxygen such as trace oxygen, constant oxygen and purity oxygen. The magnetic mechanical principle has high analysis precision and long service life. It has non-explosion-proof and explosion-proof models and can be used in industrial hazard applications.

Features

• The mechanical dumbbell type paramagnetic principle has high precision, short preheating time, quick response and good linearity,

• Direct measurement of the paramagnetic properties of oxygen with low gas interference.Compared to electrochemical sensor, it adopts non-consumable components, the normal lifespan can last over 1O years.Trace, constant, purity oxygen, multi-range is optional. LCD display, concentration curve, history data and other information display.

• RS485 signal output, relay output, compatible with various control systems. Standard 19-inch chassis design(non-explosion-proof}, can be equipped with sampling system for mast of working conditions.

• Thick carbon steel casing {explosion-proof type). explosion-proof grade up to ExdllCT6, can be used in explosive hazardous areas.

• Soft boot and watchdog functions, to keep a stable work without crash.

Specifications:

| Specification | Details |

|---|---|

Tdlas Based Cross Duct Analyzer

Description

Model: UT-IN Series

The laser gas analyzer can measure high-temperature (700°C), high-dust (50g/m3) flue gas,and can realize in-situ analysis at the work site; and the laser gas analyzer has a short response time, which is a true "real-time online" analysis instrument. It can be used to measure CO, CO2, O2, NH3, HCL, HF, CH4 and other gases. Provide real-time and accurate data for process monitoring, safety monitoring, and pollution monitoring.

Features

· High Precision, Extremely Low Drift

· High selectivity, No Cross interference

· High temperature gas can be measured, up to 700 deg C

· It can measure complex gas mixture and their component changes

· No affected by dust

· Reponse time <1s

· Long maintenance period and low cost

· long service service life

· Suitable up to 50 g/m3 dust load

Specifications:

| Specification | Details |

|---|---|