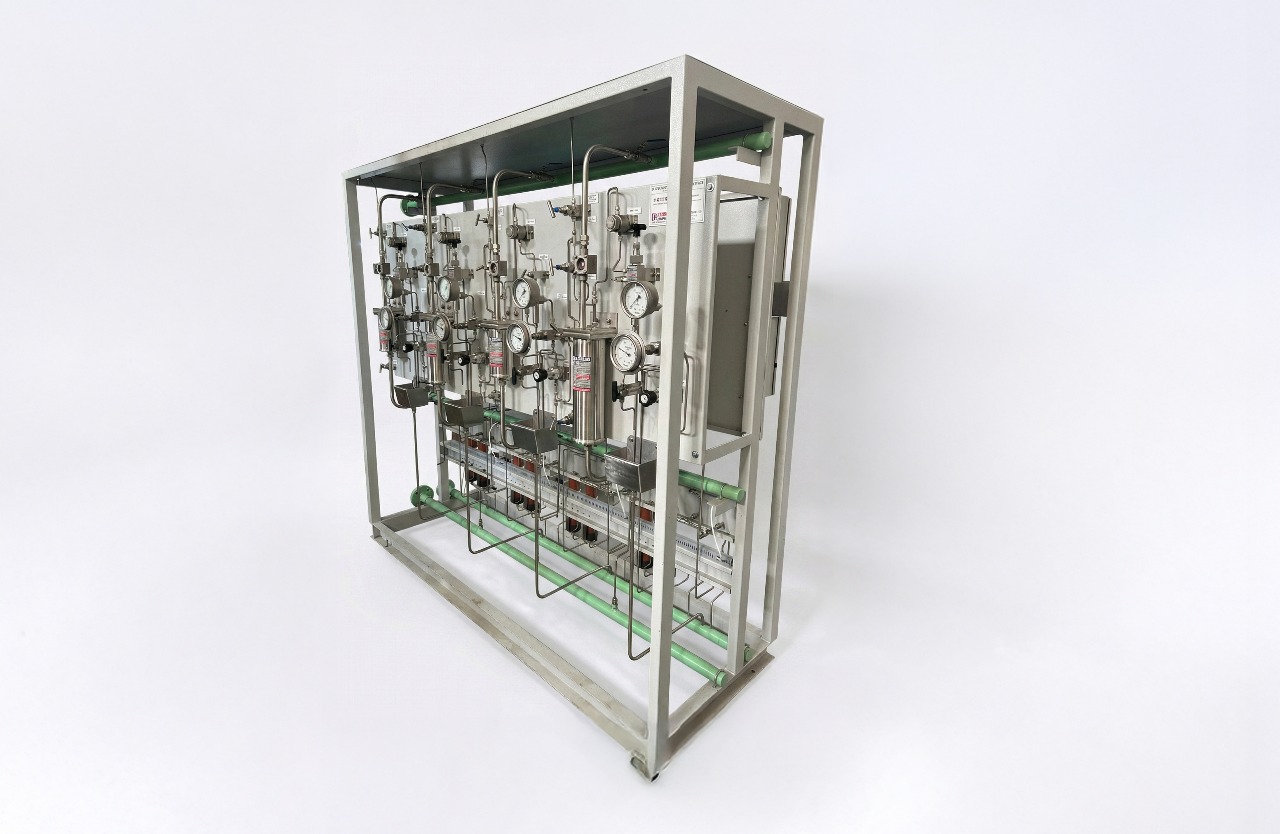

Fit Swas ( Fully Integrated And Tested Steam And Water Analysis Systems)

FIT SWAS mounted in stainless steel shelter

Shelter based SWAS inside view

Description

Steam and water analysis system (SWAS) — A well designed Steam and Water Analysis system (SWAS) can help in monitoring the critical parameters in the steam. These parameters include pH, conductivity, silica, sodium, dissolved oxygen, phosphate and chlorides. A well designed SWAS must ensure that the sample is representative till the point of analysis. The SWAS system comprised of shelters, walk-way, rack mounted, panel mounted designed as per the customer requirements are the best suited for power plants. These are safe for use, provide good working area for user & system expert, yet protects the equipment from unauthorised usage / fiddling. Hence Steam Equipments designed new concept of FIT SWAS (Fully Integrated Steam & Water Analysis System).We have designed & developed Steam & water analysis system in accordance with the recommendations of ASME PTC 19.11 Part-II.

Features

• In compliance with ASME PTC 19.11

• Analysers and Sampling system at one place.

• Easy access for operator to all instruments.

• Design provides safety to the equipment ensuring longevity and trouble-free operation.

• Can be installed and commissioned in record time.

• With MOC as FRP, CRCA or SS-316 according to customer’s requirements.

Benefits

• Longer life of equipment ensured.

• High degree of safety to the operator ensured.

• Unauthorised usage totally prevented.

• Saves lot of time on site in terms of installation as well as commissioning.

• Saves a lot of civil work, tubing, piping and cabling.

• Plug and play construction.

• Saving in manpower and material costs on site, thus reducing project costing substantially.

• Saving in utility transport.

Applications

• Large Thermal Power Plants (Typically 800 to 1000 MW per unit).

• Combined Cycle Power Plants.

• Chemical / Pertrochemical / Fertilizer / Refinery applications of sample conditioning and analysis.

Modular System

Description

Modular sampling panels for primary sampling and secondary sampling; Primary sampling module includes inlet isolation valve, blow down valve, sample cooler with cooling water inlet and outlet valve with coolant flow indicator to diagnose required flow of cooling water. Pressure reduction and high sample temperature safety valve (thermal shut off valve).

Primary cooling sampling panel consists of rotameter, Back Pressure Regulator, Pressure Gauge, Temperature Gauge and Grab Valve with Tundish.

For conditioning scheme of both, primary and secondary panel- secondary panel includes Secondary Sample Cooler with chilled water inlet and outlet valve with chilled water Flow Indicator, Rotameter, Back Pressure Regulator, Pressure Gauge, Temperature Gauge and Grab Valve with Tundish. The chiller unit is skid mounted modular type, it’s a separate unit which will be connected to secondary cooler chilled water inlet and outlet connections.

All Systems are designed in compliance with ASME PTC-19.11, USA, GDCD, UK, EPRI, VGB Standard S006-2012

Features

• Designed as per ASME PTC 19.11 recommendations.

• Design temperature of 650oC and pressure of 400 Bar.

• Compact double helix type, shell and tube sample coolers.

• All high-pressure components to pressure reducer can withstand temp up to 550oC.

• Automatic high temp shut off valves are used for high temp protection.

• No power supply required.

• No wiring required.

• Rod in tube type pressure reducer.

• Online pressure regulator cleaning.

• Back pressure regulator with SS diaphragm.

• Easy access to components.

• SS cooling water pipeline.

Benefits

• SS cooling water pipeline.

• Cost Effective system

• Accurate & stable measurement system

• Long Life Equipments

• Compact design

Applications

• Steam applications Feed water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam, Life Steam

• Main Steam Demi Water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam

• Main Steam for power stations

Combined System

Description

It consists of both wet panel and a dry panel combined into one system. It is customize built panel, which includes Primary and Secondary sampling components in one skid with indicating and control instruments like Isolation Valves, Blow Down Valves, Pressure Regulator, Pressure Gauge, Temperature Gauge, Rotameter, Grab Sample Valves are in front of the panel mounted on SS sheet with common Tundish.Dry panel components such as Sample Cooler, Filter, Cooling and Chilled Water Isolation Valves, Thermal Shut Off Valve, BPRV, Cation Column etc. are on the back of the panel. Flush mounted analyzer panel is adjacent to sample panel, which makes the combined panel compact and easily serviceable. All Systems are designed in compliance with ASME PTC-19.11, USA, GDCD, UK, EPRI, VGB Standard S006-2012

Features

• Designed as per ASME PTC 19.11 recommendations.

• Design temp: 650oc and p: 400 Bar

• Compact double helix type, shell and tube sample coolers

• All high-pressure components to pressure reducer can withstand temp up to 550oC

• Automatic high temp shut off valves are used for high temp protection

• No power supply required

• No wiring required

• Rod in tube type pressure reducer

• Online pressure regulator cleaning

• No filters used

• Back pressure regulator with SS diaphragm

• Easy access to components

• SS cooling water pipeline

Benefits

• Low maintenance Required

• Cost Effective system

• Accurate & stable measurement system

• Long Life Equipments

• Compact design

Applications

• Steam applications Feed water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam, Life Steam

• Main Steam Demi Water

• Condensate, Boiler Water

• LP Drum Water

• LP/HP Steam

• Main Steam for power stations

• Quality Analyzer system

Walkway Type System

Description

Walk in type sample Conditioning systems are specially designed as per NTPC & BHEL specifications and are suited for mid-size and large plants. These are safe for use, provide separate interface for user & system expert, thus protecting the equipment from unauthorised usage / fiddling. The deliveries of such systems can be given in a medium span.

All Systems are designed in compliance with ASME PTC-19.11, USA, GDCD, UK, EPRI, VGB Standard S006-2012

Features

• Closed type construction

• Separate interface for operator

• Easy access for operator to all essential indicating instruments

• Design provides safety to the equipment ensuring longevity and trouble-free operation

• Number of lines: Selectable from 1 to 10 (more also available on request)

• Sample temperatures than can be handled: from 30 to 600oC. (more temperatures can be handled on request)

• Sample pressures than can be handled: from 1 to 300 Kg/cm2 (more pressures can be handled on request)

• Typical size of rack (per line): 2100mm (H) x 650mm (W) x 1200mm (D). (Width will increase incrementally as per number of lines)

• Cooling water temperature: 25 to 35oC (If more, special designs are available)

• Cooling water quality: preferably DeMin water with chloride content 35ppm (If different quality water is available, special designs are available)