Online Extractive Flue Gas Analyzer

Description

Model: UT-Ex-S-N-O-H-230VAC

The NDIR gas analyzer can be used to continuously measure CO and CO2 、CH4 、SO2, NOand other gas concentration, can simultaneously measure one or more of the gas components. This Infrared gas analyzer is a multi-channel, multi-component analysis instrument. The instrument adopts the world's most advanced infrared gas detection technology. With excellent stability, selectivity and high sensitivity, it can be widely usedin boiler, power plant flue gas, chemical process, petrochemical industry, metallurgicalindustry and other fields, and can also be used for laboratory analysis

Features

• The sensor unit can bemeasured continuously SO2,NO、CO,CO2、CH4, O2、C2H4C3H8, TCH and other gasconcentration

• Multiple components can beanalyzed simultaneously

• Multi-channel 4-20 mA analogoutput and relay contactoutput.

• Automatic calibration, faultself-diagnosis, and digitalcommunication functions

• High accuracy and good stability

• ppm and mg/m3 are optional

• Very short preheating time- -5 minutes

• The instrument operation is simple, fast setting and convenient operation

• Use automatic air instrument for calibration zero (<5% CO2, zero must be calibratedwith N2)

• The interval of instrument range calibration every 3 months according to theenvironmental conditions

Specifications:

| Title | Desc |

|---|---|

| Response time from Analyser Sensor Inlet port (T90) | <40~50 seconds |

| Reheating time | 30 min |

| Communication interface | RS232/RS485 |

| Analogue output | Each parameter 4–20mA |

| Alarm output | Passive contact signals |

| Operating temperature | 0 to 50°C |

| Atmospheric pressure | 86–108 kPa |

| Relative humidity | 5 to 85 % |

| Operating power | 110VAC or 230VAC ±10%, 50Hz 2A |

| Instrument weight | approx. 15–20 kg |

Online In-situ Type Flue Gas Analyzer

Description

Model: UT-IN-S-N-O-H-230

SO2-NO2-CO2 measurement:

• This analyzer uses UV absorption (for SO₂ and NO₂) and IR spectroscopy (for CO₂) in a compact, robust sensing head with LED light sources and no moving parts, requiring virtually zero maintenance.

Accuracy is ensured through automatic zero calibration using ambient air, with CO₂ scrubbed by a long-life disposable filter (2+ years replacement interval).

• Service needs are minimal: 36V DC power (@50 VA) and RS485 digital output via a single 4-way sealed connector.

NO/H2O Measurement:

• The NO/H₂O sensor uses the same in-situ probe design as the SO₂/NO₂/CO₂ sensor but employs a Quantum Cascade Laser (QCL) as the radiation source. The QCL provides a narrow, precise IR beam, allowing measurement of a single NO absorption line free from H₂O interference for highly accurate, noise-free readings. It simultaneously measures H₂O concentration using a nearby spectral line.

• Unlike traditional chemiluminescence (maintenance-heavy) or IR/UV methods (cross-sensitivity and short lamp life issues), the QCL offers long-term stability, no moving parts, and virtually zero maintenance, with a lifetime measured in decades.

• The analyzer measures NO from <10 ppm to several thousand ppm at temperatures up to 450 °C and can be adapted for other gases (e.g., NH₃) by selecting a suitable QCL wavelength, making it ideal for applications like SCR control in coal-fired power plants.

Features

• INSITU CEMS suitable for Refineries, power plant & other industries.

• Measurement gas resolution 1 PPM and accuracy +/-2% of reading

• UV absorption spectroscopy based SO2 & NO2 measurement, Laser (QCL) based NO & H2O measurement and Infrared spectroscopy-based CO2 measurement

• Remote monitoring of system available.

• Simple Installation as per the photograph

• Light weight so easy to installation.

• Low maintenance cost

• No Shelter required

Specifications:

| Parameter | Description |

|---|---|

| Measurement | SO2, NO2, CO2, NO/H2O |

| Technology | SO2–NO2–CO2: UV absorption spectroscopyNO/H2O: Quantum Cascade Laser (QCL) |

| Range (SO2–NO2–CO2 measurement) | SO2: 0 to 500/1000 ppmNO2: 0 to 500/1000 ppmCO2: 0 to 10%(Other measurement range can be customized) |

| Range (NO–H2O measurement) | NO: 0 to 500/1000 ppmH2O: 0–20%(Other measurement range can be customized) |

| Probe MOC | SS 316 |

| Accuracy | SO2: 2 ppm or 2% of readingNO2: 2 ppm or 2% of readingCO2: 0.1% CO2NO: 1 ppm or 2% of readingH2O: 0.1% H2O |

| Resolution | SO2/NO2/NO: 1 ppmCO2/H2O: 0.1% |

| Protection level | IP65 |

| Probe length | 300mm/500mm/1000mm(Customized length as per site requirements) |

| Response time | T90 <100 sec |

| Analog Output | Each parameter 4–20mA output |

| Digital Interface | RS485 Modbus |

| Ambient temperature | -20 to 55°C |

| Power supply | 100–240VDC, ±10% FS, 50/60Hz |

| Purge | Instrument Air |

| Calibration facility | Using Calibration Standard cylinder |

| Work temperature (Flue gas temperature) | 0 to 450°C |

| Weights | <30 kg |

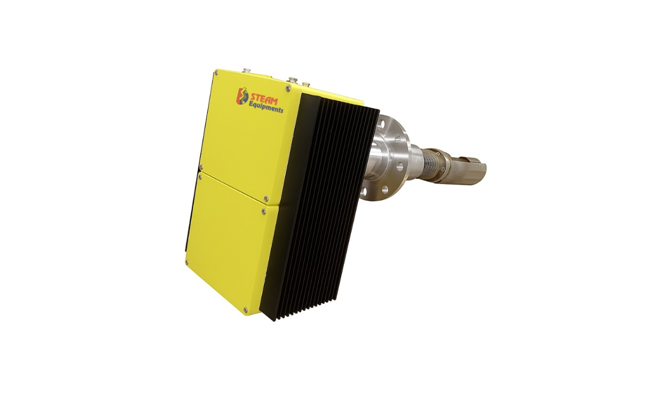

Online In-situ Ex Type Flue Gas Analyzer

Description

Model: UT-IN-S-N-O-H-230VAC

UT-IN series Flue Gas Analyzer is a highly integrated single-flange gas monitoring equipment, of which, core detection module adopts Tunable Diode Laser Absorption Spectroscopy (TDLAS), Differential Optical Absorption Spectroscopy (DOAS) gas absorption technology and Zirconia with independent intellectual property rights. The specially designed measuring cell effectively improves optical path length for gas absorption, which can measure trace gas accurately inside pipeline UT-IN series can be widely applied in online gas monitoring occasions including denitrification device, boiler flue and exhaust detection, etc. One equipment can realize online monitoring for multiple gas components, such as CO, CO2, SO2, NO, NO2, O2, H2O etc.

Features

• Adopt single-flange design with high integration

• and easy installation

• Measurement gas resolution 1 PPM and accuracy +/-2% of fs

• Remote monitoring of system available.

• Simple Installation as per the photograph

• With high-temperature flowmeter, user can

• observe flow during equipment operation

• Low maintenance cost

• Sampling measurement is free from interference of pipeline deformation, high dust and other working condition change, with strong adaptability

• No Shelter required

Specifications:

| Parameter | Description |

|---|---|

| Measurement | SO2, NO, NO2, CO, CO2, O2/H2O |

| Measurement Technology | SO2/NO/NO2: DOAS (Ultraviolet Differential Absorption Spectroscopy)CO/CO2: TDLAS (Tunable Diode Laser Absorption Spectroscopy)O2/H2O: Zirconia based Sensor |

| Measurement Range | SO2: 0 to 500/1000/2000/3000/5000 ppmNO: 0 to 500/1000/2000/3000/5000 ppmNO2: 0 to 500/1000/2000/3000/5000 ppmCO: 0 to 500/1000/2000/3000/5000 ppmCO2: 0 to 20/25%O2: 0 to 20/25%H2O: 0 to 40%(Other measurement range can be customized) |

| Probe MOC | SS316 / SS316L |

| Probe Length | 500mm / 1000mm / 1500mm / 2000mm(Customized as per site requirements) |

| Accuracy | ± 2% FS |

| Repeatability | ± 1% FS (Under Standard Condition) |

| Resolution | SO2/NO/NO2/CO: 1 ppmCO2/H2O: 0.1% |

| Zero Drift | ± 2% FS / 30 Days |

| Span Drift | ± 2% FS / 30 Days |

| Protection Level | IP65 |

| Response Time | T90 < 90 sec |

| Analog Output | Each parameter 4–20mA output |

| Digital Interface | RS485 Modbus |

| Ambient Temperature | -20 to 60°C |

| Ambient Humidity | ≤90%, Non-Condensing |

| Power Supply | 110 / 240VDC, ±10% FS, 50/60Hz |

| Instrument Air Supply | 3–5 bar, Oil-free, water-free, and dust-free air |

| Calibration Facility | Using Calibration Standard Cylinder |

| Work Temperature (Flue Gas) | 0 to 350°C |

| Weight | <45 kg |