Sample Coolers

Description

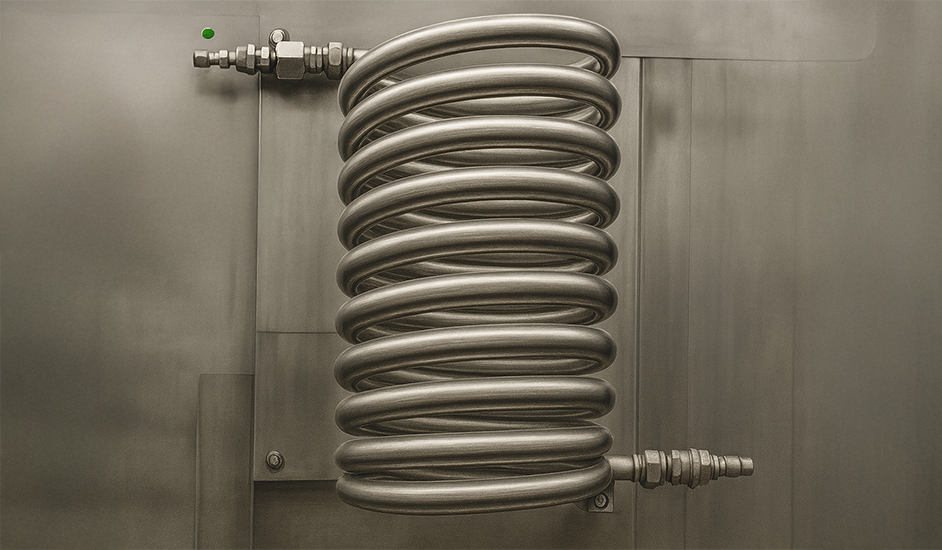

Steam Equipments Sample Cooler is a compact unit, specially designed as per ASME SECVIII, Div-1 & ASME PTC-19.11 recommendations, to handle high pressure & high temperature applications. The sample flows through a fixed volume, high pressure cylinder which is built inside the sample cooler shell, the cooling water flows through the cooling shell.These coolers as designed for counter flow cooling to achieve a very close temperature approach of the sample to coolant. The cooler is made up of the double helix coil which meets ASME D1192 requirements fitted with a baffle for maximum efficiency. The shell is mounted through flanged connections and it can be removed without disturbing sample line. Generally, SS coil is selected, however, if the chloride content of the sample is high, Inconel coil is selected otherwise it may cause stress corrosion.

Features

• Coils with double helix shape for more heat exchange.

• Compact Design: It’s very compact compared with the service it is put to. The double helix coil design makes its size almost half the size of conventional single helix designs.

• High efficiency: Very close approach temperatures with minimal cooling water requirement.

• Removable shell resulting in easy on-line shell cleaning. Facilitates routine on-site maintenance easy. Coils can be cleaned in-place.

• Built-in safety valve for CW line.

• 3 stage cooling in one shell design.

• Shell relief valve: Shell is protected with a built-in-Shell Relief Valve, thus preventing accidental pressure built-up inside the shell in case of failure.

• We can offer IBR approved sample coolers as well, as our facilities are approved by IBR.

Benefits

• In-built safety relief valve to prevent accidents in the field in case of an (unlikely) event of coil failure

• For specific applications we can offer IBR / CRN approved sample coolers

• Truly Counter-flow design

• Sample coils that are easy to replace

• No joints on the coil

Applications

• For cooling high temperature liquids to safe temperatures for continuous monitoring systems.

• Boiler water.

• Refineries and petrochemical.

• Oil & Gas.

• Process steam.

• HRSG Power Plants.

• Industries like Cement, Paper, Sugar etc.

Specifications:

• Tube designed at 250 bar and 580 °C

• Tube material is ASTM A213 TP-316 and seamlessly built

• Shell designed at 10 bar and 200 °C

• Shell material is ASTM A312 TP-304

• End connection options of ½”, ¼”, ¾”, ⅜” OD

Coil In Coil Cooler

Description

Coil in coil type heat exchangers are spirally wound, full counter flow heat exchangers well suited for a variety of applications where low flow rates of high temperature and/or high pressure fluids need cooling . These coolers are designed for counter flow cooling to achieve close approach temperature.

Features

• Designed to handle high pressure upto 250 bar & High temperature upto 580 °C samples.

• Designed in compliance ASME BPE 2007

• Close approach temperature ( 2°C)

• Minimal Cooling water requirement

• Coils are spirally wounded to ensure maximum counter flow efficiency.

• Fully drainable inner and outer coil

Refinery Cooler

Description

A Refinery Cooler is a robust heat exchange unit designed to safely and efficiently reduce the temperature of high-temperature process fluids, steam, or condensate in refinery and petrochemical plants. It plays a critical role in protecting downstream equipment, piping, and instrumentation by ensuring process streams are cooled to safe, controlled levels before further processing, sampling, or analysis.

Manufactured using high-grade, corrosion-resistant materials such as stainless steel, refinery coolers are built to withstand high pressure, high temperature, and aggressive process conditions commonly found in refinery operations. The cooler provides stable thermal performance, minimizes thermal shock, and ensures consistent outlet temperatures under continuous operation. Its compact and maintenance-friendly design makes it suitable for integration into sampling systems, SWAS panels, and refinery utility lines, enhancing overall process safety, reliability, and operational efficiency.

Features

• Designed for high-temperature and high-pressure refinery process streams

• Efficient heat dissipation to ensure safe outlet temperatures

• Corrosion-resistant construction for harsh refinery and petrochemical environments

• Compatible with sampling systems, SWAS panels, and process utility lines

• Flexible mounting options for panel, skid, or field installation

• Leak-tight design ensures safe and reliable operation

Specifications:

| Parameter | Specification |

|---|---|

| Type | Shell & Tube / Coil Type / Sample Cooler |

| Application | Refinery process fluids, steam, condensate, sampling lines |

| Inlet Temperature | Up to *350–550°C* (depending on design) |

| Outlet Temperature | Adjustable / Controlled (typically 25–40°C for sampling) |

| Operating Pressure | Up to *250 bar* |

| Cooling Medium | Cooling water / Air (as per application) |

| Body Material | SS316 / SS316L / SS304 / Carbon Steel |

| Tube Material | SS316 / SS316L |

| Connections | NPT / BSP / Flanged / Socket Weld |

| Flow Rate | As per process requirement |

| Design Standards | ASME / TEMA (as applicable) |

| Mounting | Panel-mounted / Skid-mounted / Field-installed |

| Testing | Hydrostatic & leak testing |