Digital Ph/ORP Senor

Features

• Compact all-in-one design

• Support handheld devices and in-situ applications

• Large capacity reference, long service life

• 1 inch NPT mounting thread for flexible installation

• Internal storage of calibration data

• Support offline calibration, on-site plug and play

• Optional cleaning connector for underwater cleaning

• Standard Modbus protocol, support access to standard industrial control system

Specifications:

| Specification | Details |

|---|---|

Digital TSS/Turbidity Sensor

Features

• Based on the infrared absorption and scattering light method

• Use ISO7027 method to continuously and accurately determine turbidity and suspended solids in water

• LED infrared scattering light source (850nm), stable wavelength, stable data

• Reliable performance, simple installation and calibration

• Self-diagnostic function, built-in humidity sensor and a light source detector

• Internal storage of calibration data, support offline calibration, plug and play

• Standard Modbus protocol, support access to standard industrial control system

Specifications:

| Specification | Details |

|---|---|

Digital COD Sensor

Description

The total amount of organic pollutants in the water can be measured by measuring the degree of absorption of these organic substances to 254nmwavelength ultraviolet light.

The COD 351 digital sensor adopts two light sources, one 254nm ultraviolet light, and one turbidity compensation, which can automatically eliminate the interference of suspended substances in the water, so as to achieve more stable and reliable measurement.

Features

• RS-485 output, support Modbus

• No reagents, no pollution, environmentally friendly

• Can measure COD, TOC, turbidity and temperature

• Automatically compensate for turbidity interference

• With self-cleaning brush and the maintenance cycle is longer

Specifications:

| Specification | Details |

|---|---|

Multi-parameter Controller

Description

The UVCON-EQMS Multi-Parameter Controller is a compact, microprocessor-based analytical controller designed for continuous online monitoring and control of multiple water quality parameters in industrial and utility applications. It provides reliable, accurate, and real-time measurement for critical process and utility systems.

The controller supports connection to a wide range of analytical sensors and transmitters, enabling simultaneous monitoring of key parameters such as pH, ORP, conductivity, resistivity, TDS, dissolved oxygen, and temperature, depending on configuration. Its modular design allows flexible system integration to meet specific application requirements.

The UVCON-EQMS features a high-resolution display with intuitive menu navigation for easy configuration, calibration, and diagnostics. Multiple configurable analog outputs (4–20 mA) and relay outputs enable seamless integration with PLCs, DCS, SCADA systems, and control panels for monitoring, alarm, and control functions.

Built for industrial environments, the UVCON-EQMS offers robust electrical isolation, stable signal processing, and long-term measurement reliability. It supports password-protected access, alarm logging, and fail-safe operation, ensuring data integrity and operational safety.

The UVCON-EQMS Multi-Parameter Controller is suitable for applications in power plants, water and wastewater treatment, chemical and process industries, refineries, pharmaceuticals, food & beverage, and utility monitoring systems, providing a dependable solution for centralized analytical control.

Features

• The UVCON-EQMS series multi-channel digital universal controller realizes measurement by connecting various types of sensors for detecting physical, chemical, biological.

• Connect 4 or 8 different types of digital sensors at the same time, and can display the detected or calculated measurement data of all connected sensors

• UVCON-EQMS requires these authorized sensors to upload the detected data in a special encrypted communication way to ensure that the controller can collect high-precision data more stably.

• Display the collected data on the display screen of the controller in real time, which is convenient for users to read.

• Meet a variety of installation methods, and can also provide installation accessories.

Specifications:

| Specification | Details |

|---|---|

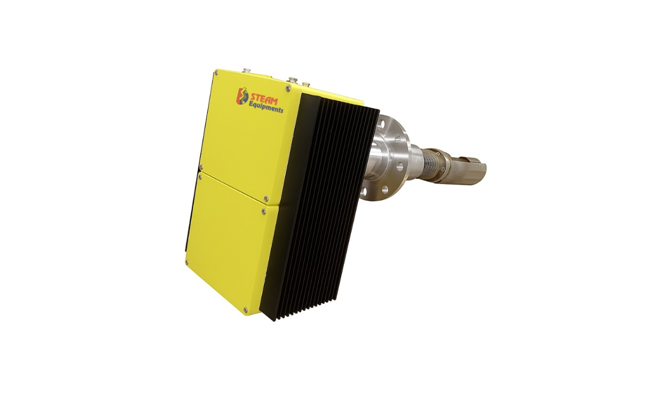

Back Scattering Dust Analyser

Description

Online dust monitoring device using the mainstream technology of laser back-scattered light principle with imported core components. BS-100 is mainly used for continuous monitoring of various sources emissions of particulate matter concentrations. It can be either equipped with CEMS, or connected with dust monitoring network by a shared set of data acquisition and processing background.

It is available for monitoring and control of soot emission, flue gas DeSOx and removal of dust for power generation boilers, industrial furnaces, industrial boilers in the thermal power, iron and steel metallurgy, petrochemical, chemical cement production, ceramics, waste incineration, etc.

Series of BS dust monitors consist of optical parts, circuit and control sections, calibrator and purge system.

The laser beam (650 nm) comes across the detection area and produces scattered light after effect with dust particles. The back-scattered light crosses the lens coverages into photosensitive detector. Analyzer circuit and control section converts light signal into signal output which is proportional to the dust concentration, and obtains dust particles emission concentration of pollution.

Features

• In-situ zeroing and span calibration

• Automatic gain control function and temperature compensation

• Smart appearance, easy installation, convinient disassembly

• Without background light influence

• Infrared remote control

Specifications:

| Specification | Details |

|---|---|

Ambient Air Quality Monitoring System

Description

An Ambient Air Quality Monitoring System (AAQMS) is a fully automated, continuous monitoring solution designed to assess and report the quality of ambient air in industrial, urban, and sensitive environments. The system continuously samples ambient air and accurately measures concentrations of critical pollutants such as PM₁₀, PM₂.₅, SO₂, NOx, CO, O₃, NH₃, along with meteorological parameters including temperature, relative humidity, wind speed, wind direction, rainfall, and atmospheric pressure.

The AAQMS is housed in a robust, weatherproof analyzer shelter engineered for reliable outdoor operation under varying climatic conditions. It includes precision analyzers, sample collection and conditioning systems, calibration and zero/span checking facilities, and a centralized data acquisition and handling system. Advanced data logging, storage, validation, and alarm functionalities ensure high data integrity and system uptime.

The system supports real-time data visualization, remote monitoring, and automatic data transmission through Ethernet, GSM, or cloud-based platforms. AAQMS enables regulatory compliance with national and international environmental standards, supports environmental impact studies, trend analysis, and provides actionable insights for air pollution control and management.

Features

• Continuous and real-time monitoring of ambient air pollutants and meteorological parameters

• High-accuracy analyzers with proven measurement technologies (UV Fluorescence, Chemiluminescence, NDIR, UV Photometry, Beta Attenuation / Laser Scattering for PM)

• Fully automated operation with minimal manual intervention

• Weatherproof, insulated analyzer shelter suitable for harsh outdoor environments

• Compliance with CPCB, MoEF&CC, USEPA, and other international standards

• Low maintenance design with easy access for servicing and calibration

• High system uptime and stable long-term performance

• Expandable and modular architecture to accommodate future monitoring requirements

Tribo Electric Type

Description

Dry dust detector adopts the world's most advanced principle of charge induction measurement, independently developed and produced by our company.The series of products are widely used in steel, metallurgy, power generation, petroleum, chemical, cement, mining and other industries gas solid two-phase flow dust concentration online measurement.Typical application: the blast furnace gas bag dust removal, TRT power generation, dry method and wet method, electrostatic dust removal, carbon concentration on-line continuous monitoring pulverized coal boiler, instead of in the past by artificial old timing sampling analysis, found that dust emission concentration in time, avoid the loss of available dust, protect gas recycle production equipment, lower consumption, deeply user welcome!

During the transportation of gas-solid two-phase fluid containing dust particles, dust particles will be charged due to the collision and friction between dust particles and dust particles and the inner wall of the pipe.When charged dust particles pass through the special measuring electrode, the measuring electrode can induce positive and negative electric charges, and the electric charges can form pA current signals in the transfer movement.The size of the ac signal is proportional to the dust mass.The dust concentration (mg/m3) can be accurately measured by further amplifying and processing the electrical signal.

Features

•. Dust concentration is measured by charge induction principle with high measurement accuracy.

•. Integrated structure, long distance of current signal transmission, strong anti-interference ability.

•. The measuring electrode is protected by spraying or casing, which improves the ability of high temperature resistance, corrosion resistance and adhesion resistance, reduces cleaning and maintenance, prolongs service life and improves product quality.

•. The main part of the sensor adopts patent design, and the air-tight connector strictly prevents the gas leakage under test and the measuring electrode is impacted out due to pressure, which guarantees the safety of the circuit and the staff.

•. Non-polar two wire connection, low power consumption operation, improve the safety of the product and field use.

•. Adopt full metal shell, waterproof, dustproof and explosion-proof.

Specifications:

| Specification | Details |

|---|---|

Cross Duct Type

Description

The DSL-340 is an optical instrument designed to measure the concentration of dust or particulate matter suspended in the exhaust gas passing through a duct, stack, or flue; typically, the exhaust gas from an industrial combustion process or air filtration system.

The DSL-340 uses the innovative Dynamic Detection Principle (DDP) which measures fluctuations in the intensity of a light beam, using a folded beam Transceiver / Reflector arrangement. Increased particulate density in the stack causes the amplitude of these fluctuations to increase. When calibrated against standard reference measurements, the amplitude of this signal relates directly to the particulate concentration in the stack, and this can be used to present as a reading in mg/m³.

Unlike the standard transmission technique, DDP has immunity to gradual reductions in the absolute intensity of the light signal and therefore, has the advantage that it is significantly less susceptible to drift with time, temperature or dirtying optics, than traditional opacity monitors using the standard transmission technique.

The light source in the Transceiver is a long life, stabilised green LED which offers long life and stable intensity. The transmitted light beam is pulsed to give complete immunity to ambient light levels. The intensity of the transmitted light is monitored at source so that any variations in the emitted light level are compensated in the received signal. The Transceiver has on board temperature measuring to provide stability over temperature.

The DSL-340 is available with or without an Operator Interface (control unit) so for the most cost effective monitoring solution the DSL-340 can operate as a “stand-alone” instrument consisting of the Transceiver head (TRX) and Reflector head, with all electrical connections (including outputs such as the alarm relays, 4-20mA and Modbus) being made inside the TRX head. As a stand-alone instrument the DSL-340 is set-up and controlled using the supplied utility software, installed on a PC or laptop, and connected via the USB connector on the TRX. When supplied with an Operator Interface (OI) all power supply and output connections are made in the OI rather than the TRX.

The DSL-340 has no moving parts, is of rugged design and has an excellent reliability record. Regular maintenance simply involves cleaning the optical surfaces which are easily accessible due to our latched head design. Both the TRX and Reflector heads are supplied with an air purge body, which when connected to a high volume source of clean air, keeps the contaminated stack gas away for the lens surfaces. An Aluminium air purge body is available for use on standard installations and a more advanced Stainless Steel air purge body is available for more demanding installations.

Features

• US EPA PS-11 compliant

• Dynamic Detection Principle (DDP) measurement technique results in increased immunity to drift

• Measurement reading as mg/m3 (when calibrated against standard reference measurements)

• Internal electronic calibration check facility

• Rugged 316L stainless steel construction

• Choice of interface options enabling easy integration

• Free utility software for PC based setup, control, and data logging

• Optional Operator Interface (OI) with different mounting configurations

Specifications:

| Specification | Details |

|---|---|

Online Extractive Flue Gas Analyzer

Description

Model: UT-Ex-S-N-O-H-230VAC

The NDIR gas analyzer can be used to continuously measure CO and CO2 、CH4 、SO2, NOand other gas concentration, can simultaneously measure one or more of the gas components. This Infrared gas analyzer is a multi-channel, multi-component analysis instrument. The instrument adopts the world's most advanced infrared gas detection technology. With excellent stability, selectivity and high sensitivity, it can be widely usedin boiler, power plant flue gas, chemical process, petrochemical industry, metallurgicalindustry and other fields, and can also be used for laboratory analysis

Features

• The sensor unit can bemeasured continuously SO2,NO、CO,CO2、CH4, O2、C2H4C3H8, TCH and other gasconcentration

• Multiple components can beanalyzed simultaneously

• Multi-channel 4-20 mA analogoutput and relay contactoutput.

• Automatic calibration, faultself-diagnosis, and digitalcommunication functions

• High accuracy and good stability

• ppm and mg/m3 are optional

• Very short preheating time- -5 minutes

• The instrument operation is simple, fast setting and convenient operation

• Use automatic air instrument for calibration zero (<5% CO2, zero must be calibratedwith N2)

• The interval of instrument range calibration every 3 months according to theenvironmental conditions

Specifications:

| Specification | Details |

|---|---|

Online In-situ Type Flue Gas Analyzer

Description

Model: UT-IN-S-N-O-H-230

SO2-NO2-CO2 measurement:

• This analyzer uses UV absorption (for SO₂ and NO₂) and IR spectroscopy (for CO₂) in a compact, robust sensing head with LED light sources and no moving parts, requiring virtually zero maintenance.

Accuracy is ensured through automatic zero calibration using ambient air, with CO₂ scrubbed by a long-life disposable filter (2+ years replacement interval).

• Service needs are minimal: 36V DC power (@50 VA) and RS485 digital output via a single 4-way sealed connector.

NO/H2O Measurement:

• The NO/H₂O sensor uses the same in-situ probe design as the SO₂/NO₂/CO₂ sensor but employs a Quantum Cascade Laser (QCL) as the radiation source. The QCL provides a narrow, precise IR beam, allowing measurement of a single NO absorption line free from H₂O interference for highly accurate, noise-free readings. It simultaneously measures H₂O concentration using a nearby spectral line.

• Unlike traditional chemiluminescence (maintenance-heavy) or IR/UV methods (cross-sensitivity and short lamp life issues), the QCL offers long-term stability, no moving parts, and virtually zero maintenance, with a lifetime measured in decades.

• The analyzer measures NO from <10 ppm to several thousand ppm at temperatures up to 450 °C and can be adapted for other gases (e.g., NH₃) by selecting a suitable QCL wavelength, making it ideal for applications like SCR control in coal-fired power plants.

Features

• INSITU CEMS suitable for Refineries, power plant & other industries.

• Measurement gas resolution 1 PPM and accuracy +/-2% of reading

• UV absorption spectroscopy based SO2 & NO2 measurement, Laser (QCL) based NO & H2O measurement and Infrared spectroscopy-based CO2 measurement

• Remote monitoring of system available.

• Simple Installation as per the photograph

• Light weight so easy to installation.

• Low maintenance cost

• No Shelter required

Specifications:

| Specification | Details |

|---|---|

Online In-situ Ex Type Flue Gas Analyzer

Description

Model: UT-IN-S-N-O-H-230VAC

UT-IN series Flue Gas Analyzer is a highly integrated single-flange gas monitoring equipment, of which, core detection module adopts Tunable Diode Laser Absorption Spectroscopy (TDLAS), Differential Optical Absorption Spectroscopy (DOAS) gas absorption technology and Zirconia with independent intellectual property rights. The specially designed measuring cell effectively improves optical path length for gas absorption, which can measure trace gas accurately inside pipeline UT-IN series can be widely applied in online gas monitoring occasions including denitrification device, boiler flue and exhaust detection, etc. One equipment can realize online monitoring for multiple gas components, such as CO, CO2, SO2, NO, NO2, O2, H2O etc.

Features

• Adopt single-flange design with high integration

• and easy installation

• Measurement gas resolution 1 PPM and accuracy +/-2% of fs

• Remote monitoring of system available.

• Simple Installation as per the photograph

• With high-temperature flowmeter, user can

• observe flow during equipment operation

• Low maintenance cost

• Sampling measurement is free from interference of pipeline deformation, high dust and other working condition change, with strong adaptability

• No Shelter required

Specifications:

| Specification | Details |

|---|---|