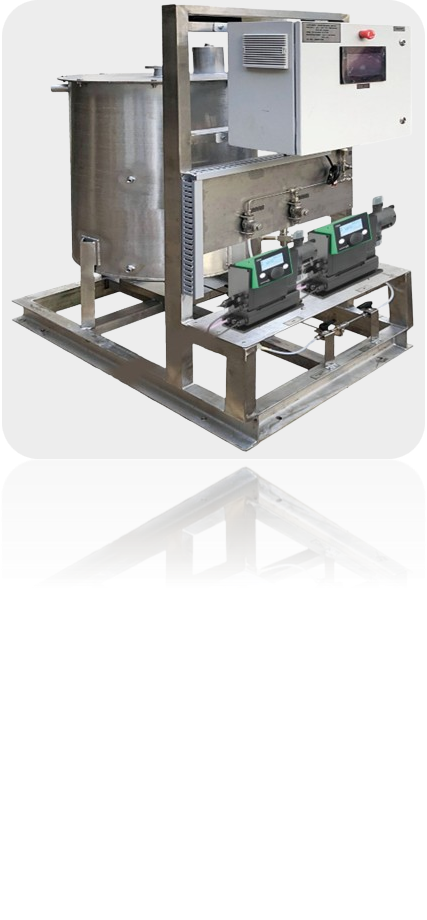

Chemical Dosing System

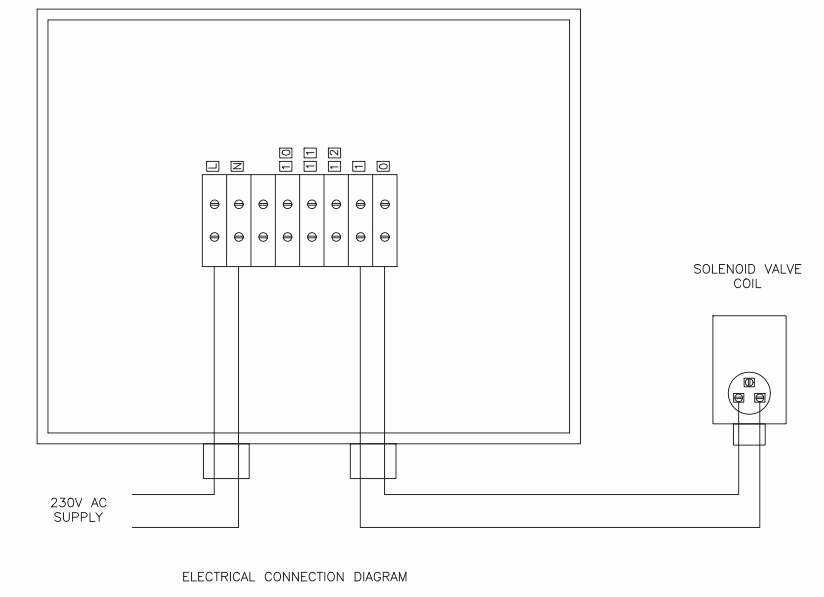

Blowdown System

Thermostatic Air Vent Trap – Slavt76-vh

Deaerator Head – Slda 95

Flash Vessel – Slfv 96

Vaccum Breaker - Slvb 76

Condensate Recovery Pumping Trap – Slcrpt 75

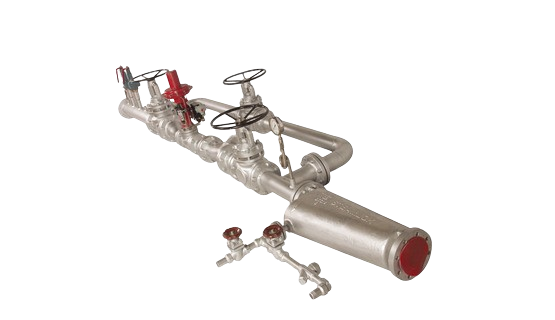

Pressure Reducing Station (prs / Prdsh) - Slprs 97

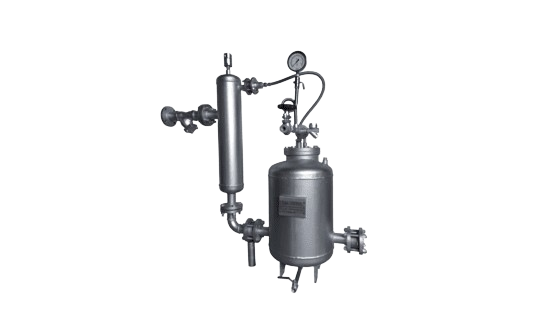

Condensate Recovery Pump – Slcrp 75

Strainers - Slstr 15/25

Moisture Separators - Slsep 25

Thermostatic Air Vent – Slavt 76 Vh

Thermostatic Steam Trap – Sltst 35

Thermostatic Pharma Trap - Slsst 79

Ball Float Steam Trap – Slft 76 (15nb, 20nb, 25nb)

Eco Ft-70

Ball Float Trap - Slft 25 (40nb, 50nb)

Ball Float Trap - Slft 25 (15nb, 20nb, 25nb)

Ball Float Trap – Slft 75 (40nb, 50nb)

Ball Float Trap – Slft 75 (15nb, 20nb, 25nb)

Thermodynamic Steam Trap – Sltt 85

Thermodynamic Compact Module – Slcmtt35-c (15nb, 20nb, 25nb)

Thermodynamic Trap – Sltt 87/88

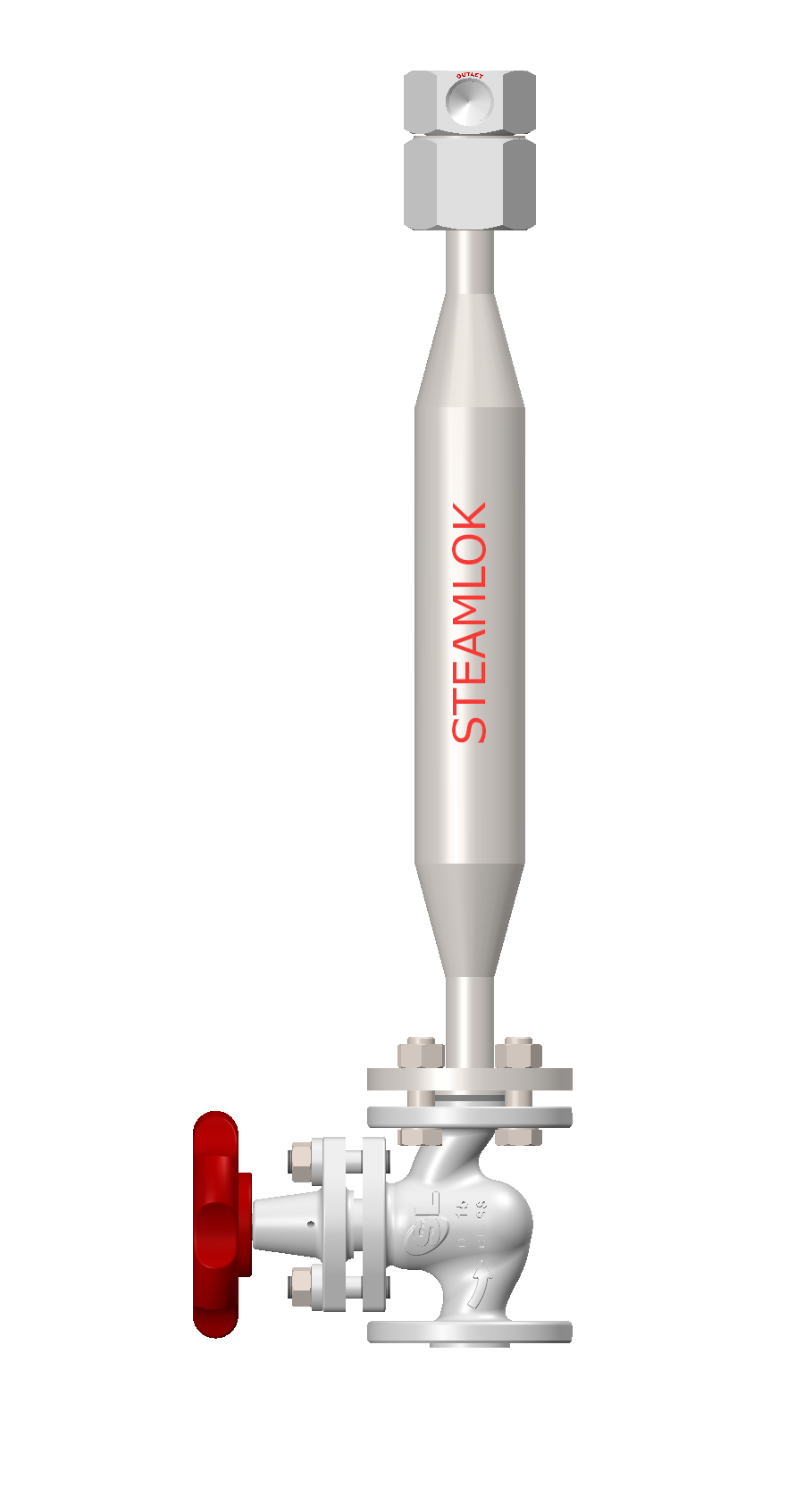

Thermodynamic Trap - Sltt 76

Disc Check Valve - Sldcv 77

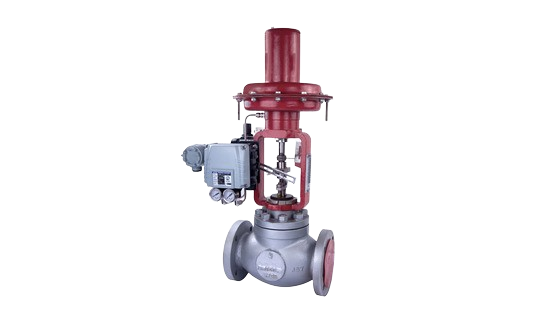

Control Valve (prv/tcv)

Piston Valves - Slpv25

Piston Valves-slpv35