Description

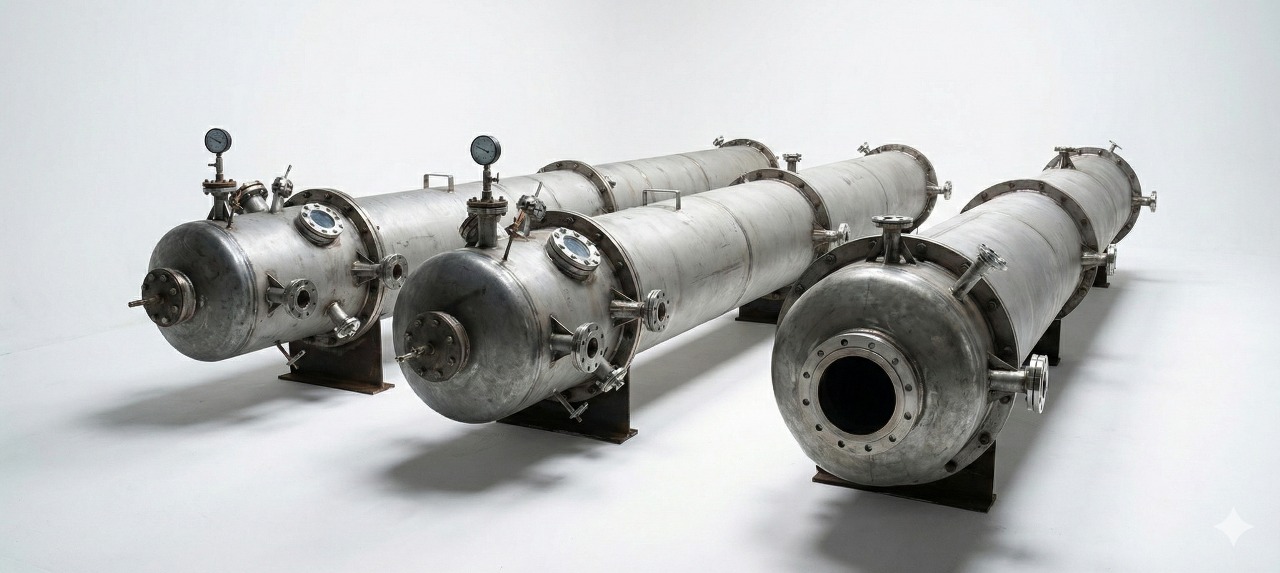

Agitated Reactors are essential components in various industrial processes, especially in chemical, pharmaceutical, and food industries. They play a crucial role in mixing, blending, and maintaining uniformity of liquids or slurries. We design and manufacture Agitators and Reactors ranging from 50 liters to 100,000liters. We design and manufacture reactors half coil jackets, with-limpet, and shell jackets, which can be enveloped by an insulation material of choice. We manufacture Agitators and Reactors for varioushigh-pressure, vacuum and atmospheric applications such as Resin production, Blending, Oil Field Chemicals, Lube Oil, Hydrogenation, Fermentation, Paints, Dyes & Pigments, Chemical Processing, Food & Beverage, and Water Treatment. We ensure high process reliability, homogenous mixing result, high efficiency, and low operating costs.

Features

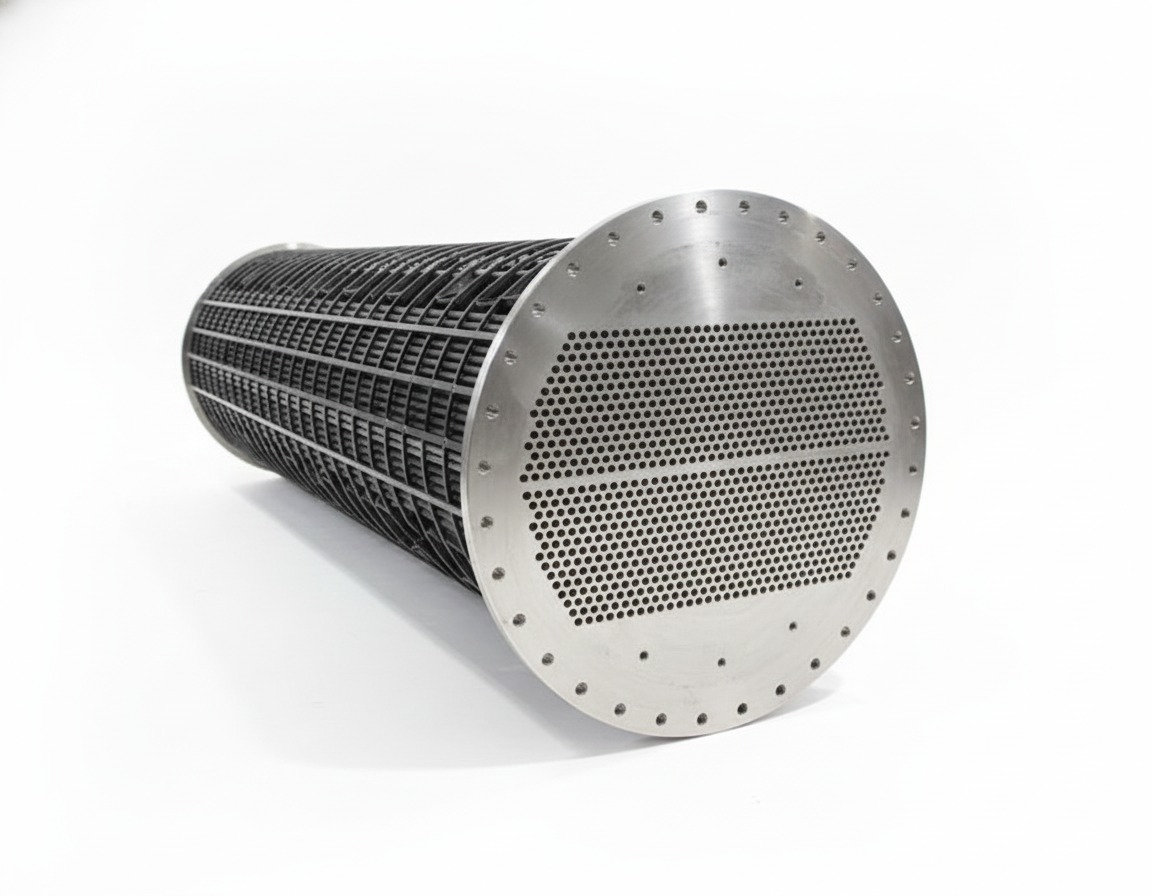

- • Mixing Mechanism - Equipped with an agitator (e.g., impellers, paddles, or turbines) to ensure uniform mixing of reactants. Promotes mass transfer and uniform concentration distribution.

- • Heat Transfer - May include jackets or internal coils for heating or cooling to maintain optimal reaction temperature. Efficient heat exchange is crucial to prevent hotspots and ensure temperature uniformity

- • Versatility - Can handle a wide range of viscosities, from low-viscosity fluids to highly viscous mixtures. Suitable for various reaction types: homogeneous, heterogeneous, and multiphase reactions.

- • Pressure and Temperature Control- Can operate at atmospheric, high, or vacuum pressures. Designed for reactions requiring precise temperature and pressure control.

Specifications:

- • Vessel Capacity 100 Ltrs. to 50,000 Ltrs.

- • Pressure Range Full Vacuum to 30 Kg / cm².

- • Torque Up to 240 KNm.

- • Mounting Positions – Vertical , Inclined and Horizontal

- • Impellers – Flat Blade and Disc Turbine, Propellers , Pitch Blade, Hydrofoil , Anchor etc.

- • Material of Construction – Stainless steel 304L,316L , Duplex , Mild Steel Rubber Coated.