Zirconia Oxygen Analyzer

Description

MODEL: OXYMON

OXYMON Series Zirconia oxygen analyzer is an analyzer used to monitor and control the oxygen concentration of combustion gases, boilers and flue gas in industrial furnaces. It is widely used in industrial fields requiring a large amount of energy - such as steel mills, power plants, petroleum and petrochemical, ceramics, paper, food or textile industries, as well as various types of incinerators and medium/small boilers. In these areas, it can help save energy. It can also reduce the emissions of CO2, SOx and NOx by controlling complete combustion, and contribute to protecting the earth's environment, preventing global warming and air pollution.

The zirconia oxygen analyzer consists of a detection unit (oxygen probe) and a control unit (transmitter). Among them, the detection unit is installed on the flue, and the detector is composed of a dust proof device, zirconia tube, heating furnace, thermocouple, gas conduit, junction box and shell. The whole device adopts a fully enclosed structure to increase the sealing ability of the whole device and improve the service life. The control unit is the terminal for the user to operate the integrated functions, including the operation panel, the display interface, and the 4-20mA current output port. The oxygen analyzer with automatic calibration also includes a standard automatic order box.

Features

• Easy to Use and Low Maintenance

• The Sensor adopts Ion coating technology ,which has strong anti-oxidation ability

• long service service life

• The Unique thermal diffusion reference design does not need special reference air pump/Instrument Air

• Extremely Low Oxygen potential long-terms drift

• High measurement accuracy and stable and reliable data

• The sensor adopts unique welding process ,which has high sealing performance and No leakage

Specifications:

| Model No. | OXYMON |

|---|---|

| Digital Output | RS485 Modbus (Optional) |

| Measuring Principle | Zirconia Oxide |

| Relay Output | 1 Nos Potential Free |

| Measuring Range | 0–25% (User Configurable) |

| Display and Installation Mode | LCD, Wall Mount, External Display |

| Accuracy | ± 0.5% FS |

| Ambient Temperature | -20°C to +65°C |

| Repeatability | ± 0.5% FS |

| O₂ Probe Material | SS316L or SS304 |

| Low Detection Limit | 0.01% |

| O₂ Probe Length | 200mm to 3000mm (Customizable) |

| Operating Temperature | 0–700°C (Customizable up to 1400°C) |

| O₂ Probe Flange Connection | DN50 (2”) / DN100 (4”) (Customizable) |

| Operation Pressure | -10 KPa to +5 KPa |

| O₂ Probe Filter Material | Ceramics (As per dust load) |

| Flue Gas Flow Rate | 0–50 m/s |

| O₂ Probe Mounting Angle | Horizontal, Vertical Down |

| Response Time | T90 < 5 Sec |

| Detection Type | Insert Directly |

| IP Grade | IP65 / IP66 |

| Process Connection | DN50 / DN100 Flange (Size Customized as per requirements) |

| Power Supply | 110VAC / 230VAC, 50/60Hz, 250VA |

| Calibration | Manual / Auto (Optional) |

| Analogue Output | 4–20 mA Isolated, 500Ω Max |

| Standard Accessories | Probe Protection Tube, Mounting Spool Piece, Interconnection Cable, and Manual Cal/Auto Cal Kit |

Oxygen Analyser (SEL)

Description

MODEL: OXYMON-ZPM

It is widely used in N2 reflow furnace, N2 direct flow furnace, air separation device, gas puritymanagement, protective inert gas, ferrite sintering furnace and other environments to measureoxygen concentration

Features

• The imported new-type longevously zirconia detector is with high accuracy and a rapid response speed for features, etc.;

• N2 or O2 Display mode available;

• The auto-compensation system for temperature with high accuracy could eliminate the influence from the environment temperature;

• The accurate measurement of oxygen concentration among the range of ppm~% can be met through one-point calibration in the air;

• The size is small and easy to maintain;

• The auto-compensation system for temperature with high accuracy could eliminate

• the influence from the environment temperature.

• The upper and lower alarm limits can be set freely among the whole range

Specifications:

| Parameter | Description |

|---|---|

| Model No. | OXYMON-ZPM |

| Measurement Display | O2 or N2 |

| Measuring Principle | Zirconia |

| Measuring Range | 0–10/100/1000 PPM / 21% (User Configurable) |

| Accuracy | ± 1.5% FS |

| Repeatability | ± 1.0% FS |

| Operating Temperature | 0–60°C |

| Ambient Temperature | -10–50°C |

| Sample Mode | Sample Gas In |

| Sample Gas Flow | 300–500 ml/min |

| Sample Gas Pressure | 95 kPa – 105 kPa |

| Sample In & Out Port Size | 6 mm |

| Response Time | T90 < 30 sec |

| Background Gas | Nitrogen and Oxygen Mixed Gas |

| Power Supply | 85–240 VAC, 50/60Hz, 250VA |

| Analogue Output | 4–20 mA Isolated, 500Ω max |

| Size | 80 × 160 × 142 mm (H × W × D) |

| Install Cut Out | 76 × 151 mm (H × W) |

| Relay Output | 1 Nos Potential Free |

| Service Life | > 22000 hours (Under Normal Use) |

| Install Mode | Frame mount or retaining clamp carried by the Oxygen sensor |

Portable Oxygen Analyzer (AST)

Description

AST-1012 portable PPM O2 analyzer is powered by a rechargeable battery. AST-1012 PPM O2 analyzer offers user selectable any range from 0-5 PPM to 0-25%. Display resolution of 0.01PPM. Analog signal output is locked on the selected range. Fast recovery from air to 10 PPM in under 45 minutes.

AST-1012 portable PPM O2 analyzer comes with a standard PPM O2 sensor model AST-333. The AST-333 PPM O2 sensor is compatible with inert and gaseous hydrocarbon gas streams, and has 18 months expected operating life.

AST-1012 portable O2 analyzer can be used in an extended operating temperature range of -10°C (14°F) with optional Z series PPM O2 sensor model AST-333-Z. In addition to extended temperature range, the Z-Series sensors show excellent compatibility with gas streams containing any level of CO2. No routine sensor maintenance, other than periodic calibration, is needed. Analyzer is fitted with quick connect sample inlet and outlet fittings for quick and easy operation.

Features

• User Selectable Range From 0-5 PPM to 25%

• Output Locking on Selected Range

• Analog output 0-1 VDC Full Scale

• Fine Tuned Temperature Compensation for Enhanced Accuracy

• Barometric Pressure Compensation

• Intrinsically safe design complies with Class I Div I Group IIC when used with recommended battery

Specifications:

| Measurement Range | User selectable from 0-5 PPM - 21% |

|---|---|

| Display | Bright 2-Line LED |

| Output Lock | 0-1V locked on user selectable range. |

| Accuracy | < 2% of FS at constant operating conditions |

| Linearity | +/-1% after calibration |

| Temperature Compensation | Fine tune on low PPM range for enhanced stability |

| Barometric Pressure Compensation | Optional |

| Calibration Method | Certified Span Gas or air, Recommended Calibration interval 30 days |

| Gas Connections | 1/8 |

| Menu Controls | Membrane Switch, Menu driven selection of Analysis Range, Display Resolution, Signal Filter Strength, Fine Tune Temp Compensation, System Functions |

| Sensor | AST-333 for inert gas analysis |

|---|---|

| Response Time | : 90% of Step Change in 30 sec |

| Repeatability | +/-1% over all ranges |

| Recommended Sample Flow Rate | 1-2 SCFH, vent to atmosphere |

| Sample System Included | SS 316 Sensor Housing with Compressing Tube Fittings Gas Connectors |

| Sensor Model | AST-333 inert gases, AST-333Z for gases containing more than 0.5% CO2 |

| Expected Sensor Life | 24 months @ 25ºC and 1 atm |

| Battery Life | 30 days continuous on a single charge |

| Operating Temp: Range | 5ºC to 45ºC |

| Enclosure4 | IP67 Painted Aluminum 7.3” x 5.3” x 3. |

| Warranty | 12 months trnasmitter; 12 months sensor |

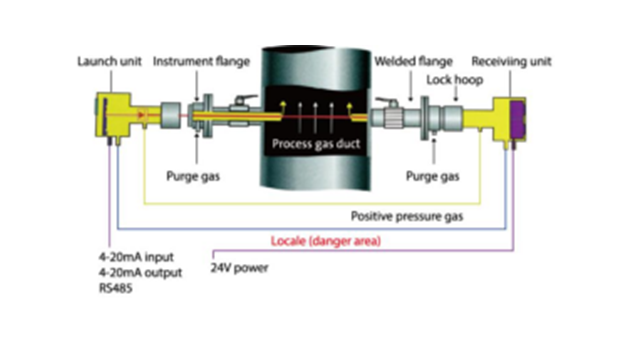

Tdlas Based Cross Duct Analyzer

Description

Model: UT-IN Series

The laser gas analyzer can measure high-temperature (700°C), high-dust (50g/m3) flue gas,and can realize in-situ analysis at the work site; and the laser gas analyzer has a short response time, which is a true "real-time online" analysis instrument. It can be used to measure CO, CO2, O2, NH3, HCL, HF, CH4 and other gases. Provide real-time and accurate data for process monitoring, safety monitoring, and pollution monitoring.

Features

· High Precision, Extremely Low Drift

· High selectivity, No Cross interference

· High temperature gas can be measured, up to 700 deg C

· It can measure complex gas mixture and their component changes

· No affected by dust

· Reponse time <1s

· Long maintenance period and low cost

· long service service life

· Suitable up to 50 g/m3 dust load

Specifications:

| Parameter | Description |

|---|---|

| Model No. | UT-IN Series |

| Measuring Principle | TDLAS (Tunable Diode Laser Absorption Spectroscopy) |

| Optical Channel Length | < 15 meter |

| Response Time | < 1 sec |

| Accuracy | ± 1% FS |

| Span Drift | ± 1% FS |

| Repeatability | ± 1% FS |

| Maintenance Intervals | < 2 times / year, Clean optical window (No consumables needed) |

| Calibration Intervals | < 2 times / year |

| Operating Temperature | Up to 700°C |

| Protection Class | IP67 |

| Wetted Parts | SS316L |

| Area Classification | Suitable for Hazardous area (Ex d IIC T5) |

| Analog Signal | 4–20mA Isolated Current Output (max load 600 ohms) |

| Analog Input | 4–20mA Current (Temp., Pressure compensation) Optional |

| Digital Output | RS485 / RS232 |

| Relay Output | 3-wire output (24V, 1A) |

| Power Supply | 24VDC / 110VAC–230VAC, 50/60Hz, <30W |

| Purge Gas | 3 to 8 Bars Industrial N2, Purification Instrument Air |

| Ambient Temperature | –30 to 65°C |

| Transmitter & Receiver Enclosure Material | Cast Aluminum Shell |

| Installation | Cross Duct In-situ Installation |

| Process Connection | Flange (Size Customized as per Requirements) |

| Standard Accessories | Mounting Spool Piece, Root Valve, Interconnection Cable, and Manual Calibration Kit |

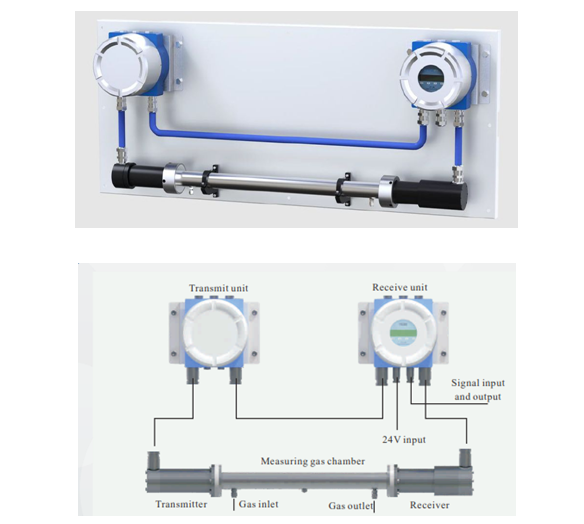

Tdlas Based Online Analyzer

Description

UT-IN is a flameproof bypass type tunable laser gas analyzer for industrial on-line analysis and environmental on-line monitoring, especially suitable for harsh working condition such as high temperature, high humidity, high dust, and high board. The analyzer contains auto purge function with greatly reduces maintenance cost.

UT-IN laser gas analyzer consists of transmitter, received and gas cell. The transmitter drives the tunable diode to emit laser of certain wavelengths, which passes through the gas cell, then reaches the receiver. The receiver performs signal processing to obtain second harmonic signal, then calculates the concentration according to the relationship between the second harmonic signal and the gas concentration.

Features

• Suitable for harsh working conditions such as hightemperature, high humidity, high dust, high pressure,

• and for small pipes where a are not suitable for inside measurement occasions.

• Integrated structure design, high reliability and

• Stability

• “Single Line Spectrum”

• Technology, free from interface of background

• Gas.

• Innovative Hall button design, high sensitivity,

• Easy operation.

• Adopts imported TO encapsulate semiconductor laser, optical noises are restrained with antireflective coating end cap.

• Easy installation and operation

• Low maintenance

Specifications:

| Parameter | Description |

|---|---|

| Model No. | UT-IN Series |

| Measuring Principle | TDLAS (Tunable Diode Laser Absorption Spectroscopy) |

| Measuring Gas Chamber Length | 200–1000 mm |

| Measuring Gas Chamber MOC | SS316L / Hastelloy (Can be customized) |

| Preheating Time | < 15 min |

| Response Time (T90) | < 30 sec (related to the working condition) |

| Accuracy | ± 1% FS |

| Span Drift | ± 1% FS |

| Repeatability | ± 1% FS |

| Maintenance Intervals | < 2 times / year, Clean optical window (No consumables needed) |

| Calibration Intervals | < 2 times / year |

| Operating Temperature | Up to 700°C |

| Protection Class | IP66 |

| Area Classification | Suitable for Hazardous area (Ex d IIC T6) |

| Analog Signal | 4–20 mA Isolated Current Output (max load 500 ohms) |

| Analog Input | 4–20 mA Current (Temp., Pressure compensation) Optional |

| Digital Output | RS485 / RS232 |

| Relay Output | 3-wire output (24V, 1A) |

| Power Supply | 24VDC / 110VAC–230VAC, 50/60Hz, < 40W |

| Purge Gas | 2 to 8 Bars Industrial N2, Purification Instrument Air |

| Ambient Temperature | -20°C to 60°C |

| Transmitter & Receiver Enclosure Material | Cast Aluminum Shell |

| Installation | Wall Mount |

| Sample In / Out Connection | 6mm / 8mm (Size Customized as per Requirements) |

Paramagnetic Oxygen Analyzer

Description

Model No: ZY-OXY-PM/PMD

The ZY-OXY-PM series paramagnetic gas analyzer is based on the characteristics of oxygen with high paramagnetic. It can detect various concentrations of oxygen such as trace oxygen, constant oxygen and purity oxygen. The magnetic mechanical principle has high analysis precision and long service life. It has non-explosion-proof and explosion-proof models and can be used in industrial hazard applications.

Features

• The mechanical dumbbell type paramagnetic principle has high precision, short preheating time, quick response and good linearity,

• Direct measurement of the paramagnetic properties of oxygen with low gas interference.Compared to electrochemical sensor, it adopts non-consumable components, the normal lifespan can last over 1O years.Trace, constant, purity oxygen, multi-range is optional. LCD display, concentration curve, history data and other information display.

• RS485 signal output, relay output, compatible with various control systems. Standard 19-inch chassis design(non-explosion-proof}, can be equipped with sampling system for mast of working conditions.

• Thick carbon steel casing {explosion-proof type). explosion-proof grade up to ExdllCT6, can be used in explosive hazardous areas.

• Soft boot and watchdog functions, to keep a stable work without crash.

Specifications:

| Parameter | Description |

|---|---|

| Model | ZY-OXY-PM: non-explosion proofZY-OXY-PMD: explosion proof |

| Measure Range | O2: 0–5% / 15% / 30% / 100% VOL |

| Principle | Customized Paramagnetic |

| Accuracy | ± 0.1% VOL |

| Resolution | 0.01% / 0.1% VOL (based on the range) |

| Repeatability | ± 0.8% |

| Zero Drift | ± 0.5% FS / 7d |

| Span Drift | ± 0.5% FS / 7d |

| Response Time | ≤ 5s (T90) |

Coal Mill Co Online Monitoring System

Description

The UV-EX-COAL-C-230VAC coal mill CO online monitoring system is an early warning system for high CO concentrations. It reacts very quickly to changes in CO content before an open flame occurs. This system can provide an early warning of a coal mill fire based on the CO concentration produced during incomplete combustion, preventing damage to equipment and personnel. The GCEM1100CM coal mill CO online monitoring system consists of four parts: a sampling probe assembly, a preprocessing unit, an analysis unit, and a display unit. Based on dispersive infrared (NDIR) photoelectric detection technology and our company's mature preprocessing system, it features long service life, strong anti-interference ability, good stability, high measurement accuracy, and low maintenance difficulty.

Features

• Utilizing the principle of non-dispersive infrared (NDIR) and optical long-path absorption cell technology, it achieves high measurement accuracy and long service life;

• It includes an automatic calibration function to prevent gas detection drift.

• Configure zero-point calibration and full-scale calibration to ensure excellent linearity;

• The system employs a direct extraction sampling method with full-process high-temperature heating, ensuring high reliability, accurately reflecting the composition and content of flue gas without additional errors, and providing high measurement accuracy. The system also offers diverse configurations, allowing for the selection of electrochemical measurement modules based on actual operating conditions.

• The probe filter is manufactured using a special process, and the automatic purging configuration of the sampling pipeline ensures continuous sampling and long-term reliable operation of the system under high dust conditions.

Specifications:

| Measurement methods: | non-dispersive infrared spectroscSampling method: Extractive sampling opy, electrochemical... |

|---|---|

| Measurement range | CO: 0-500-1000ppm; expandable to Operating voltage:AC220V+20%, 50/60Hz CO2 and O2 |

| Output signal | 4-20mA/RS232/RS485 |

| Measurement accuracy | ±2%FS |

| Linearity error | ±2%FS |

| Response time | <60s (NDIR) |

| Repeatability | ≤1% |

| Zero/range drift | ≤2%FS/24h |

| Protection rating | IP65 |

| Rack dimensions | 600*350*600mm |

| Explosion-proof | The system can be customized to be explosion-proof. |

| Operating temperature/relative humidity | (-10~50)℃/≤85%RH, no condensation |

| Compressed air | oil-free, clean, and dry air, pressure 5-7 bar, flow rate less than 20 L/min |

| Repeatability | ≤1% |

| Compressed air | oil-free, clean, and dry air, pressure 5-7 bar, flow rate less than 20 L/min |